Digital regrinding handling

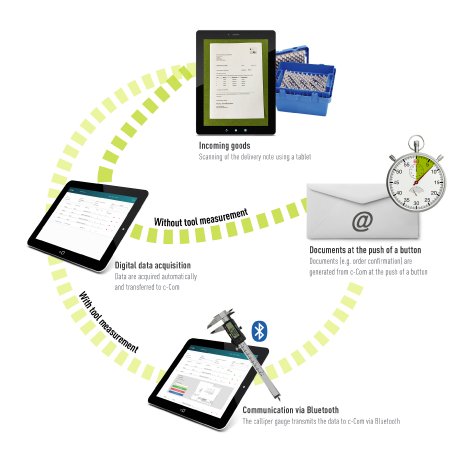

c-Com GmbH has developed a regrinding software that makes regrinding handling significantly easier and faster. It helps in total to save up to 75 percent of the time for the incoming goods. The delivery note is first scanned, for example using a tablet. The data are thereby recorded automatically and transferred to the regrinding software. All the relevant documents such as order confirmation, service report or invoice can then be created at the push of a button.

Fixed tools, such as tools with a defined minimum length, naturally still have to be inspected and measured. But the software makes even this step far simpler and faster. The length is measured using a measuring device networked with the c-Com software and compared with the values stored in the software. The operator is informed automatically if regrinding is possible or not. And if the tool has already been personalised with a QR/DMC code, the regrinding software also offers the possibility of digitally tracking the tool history. The number of previous regrindings of the tool and whether (further) regrinding is possible can be seen then immediately after scanning the code.