Here are just a few of the exciting capabilities in Gocator 6.1:

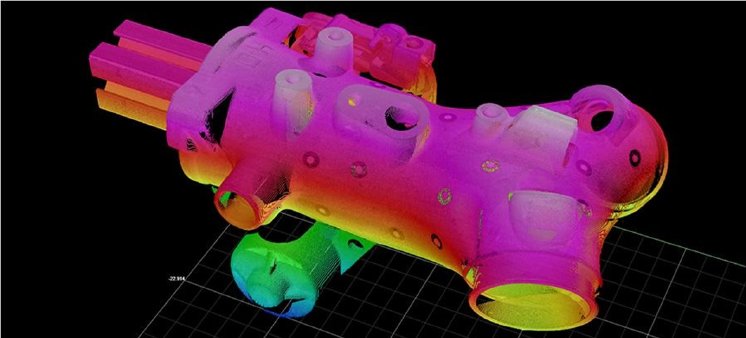

Advanced Shape Measurement of 360º Surface Data

Now users can transform multiple 3D point clouds into “meshed” surface data for use in high-precision shape measurement and inspection. Mesh data consists of interconnected data points that form a continuous, 360º surface representing the object’s complete geometry that leverages high accuracy 6DoF alignment for wide and ring type multi-sensor layouts. Users can then apply any of Gocator’s built-in Surface tools to perform advanced measurements on the meshed surface (e.g., measuring features on the sides of objects).

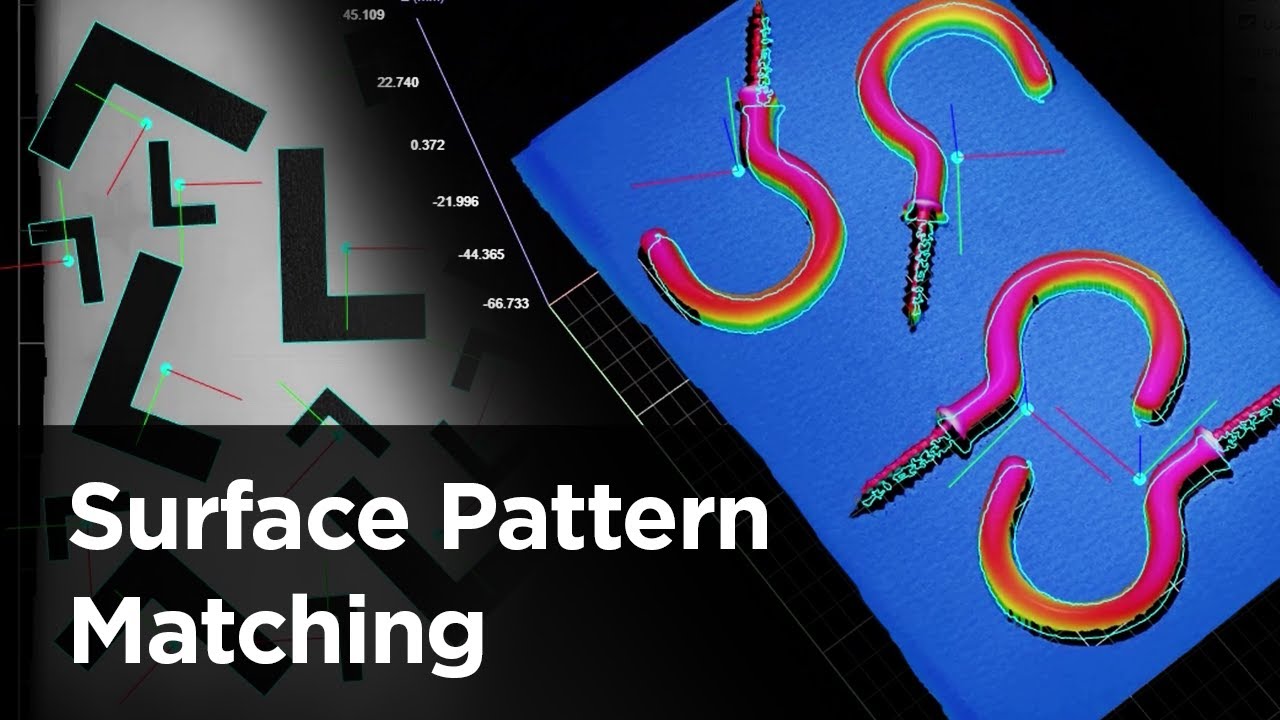

New Part and Feature Locator for 2D Intensity and 3D Heightmap Surfaces

The new Surface Pattern Matching tool is an industry-first that allows users to implement contour-based part matching to locate parts and features from 2D or 3D data regardless of scale, orientation, partial occlusion, distortion, contrast or height reversal, and overlapping patterns. Surface Pattern Matching allows the user to find one or more patterns simultaneously in a single scan cycle, which is especially useful when scanning complex parts or surface features that have multiple patterns of interest.

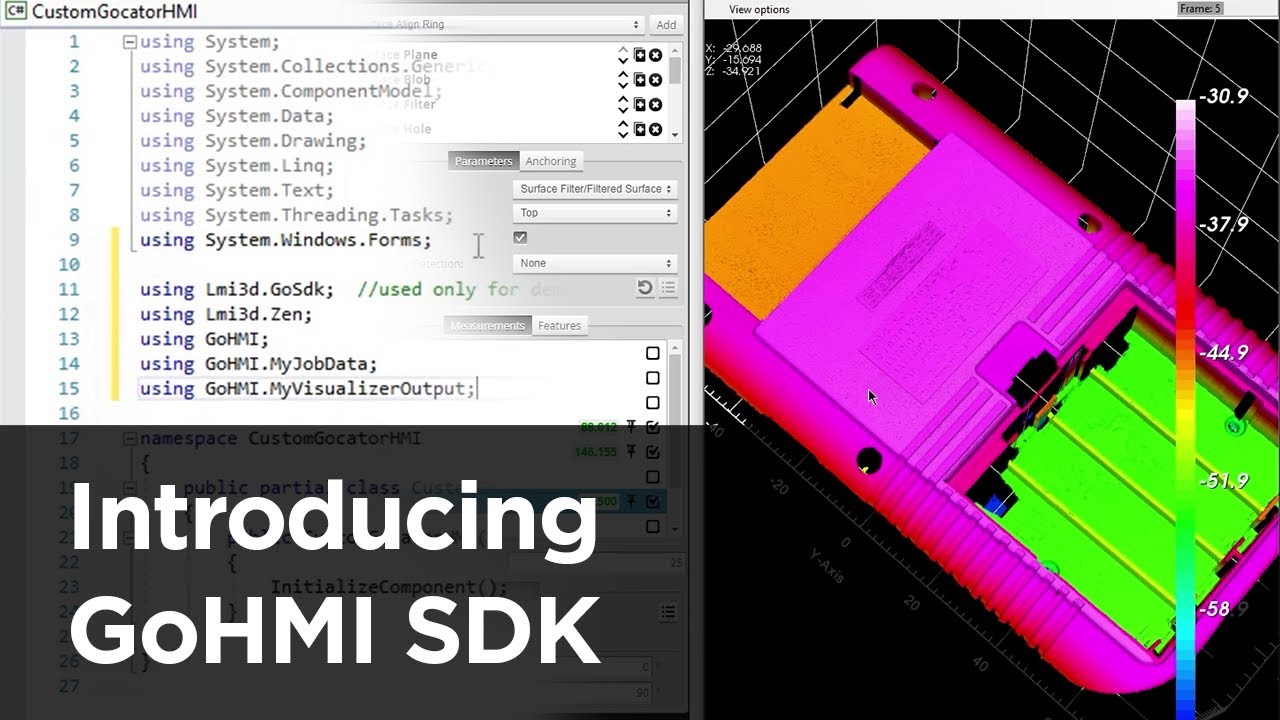

Support For Custom HMI Development

Using the new GoHMI SDK, programmers can now develop their own Gocator®-to-factory human machine interface (HMI) using Visual Studio––making it much easier to develop a rich, interactive operator user experience customized to their inspection needs.

“The introduction of mesh data support from multi-view scans and an industry first combined 2D/3D pattern matching tool gives our customers the capability for solving both 2D and 3D inspection applications in one web-based user experience!” said Chi Ho Ng, LMI’s Vice President of Technology.

Other new tools and improvements for you to explore include:

- Specialized translucent spot detection for scanning and inspection of semi-transparent materials

- Surface Cylinder tool for increased flexibility in measuring cylindrical objects/features

- Support for fixed-mount G3 sensor-robot calibration (eye-to-hand), useful in applications such as bin picking (when the G3 sensor is mounted over a tote / bin), or in welding and assembly applications

If you already own a Gocator®, you can download firmware 6.1 and upgrade your sensor for free here.