At the LogiMAT 2019, the sensor specialist Leuze electronic presented its industry-specific knowledge in intralogistics and its expertise in Safety@work. Over 55 years of experience in this particular industrial field have made the sensor people experts in intelligent, cost-efficient sensor solutions for use in conveyor and storage systems. Together with its customers, the optical sensor manufacturer from Owen/Teck develops specialized, cost-efficient solutions that are tailored to the individual needs of the customer. The focus of the company's trade fair appearance this year was on effective and safe sensor solutions for continuous conveyors, high-bay storage devices and automated guided vehicles (AGVs). A wide variety of sensors for guarding AGVs were showcased on a live object:

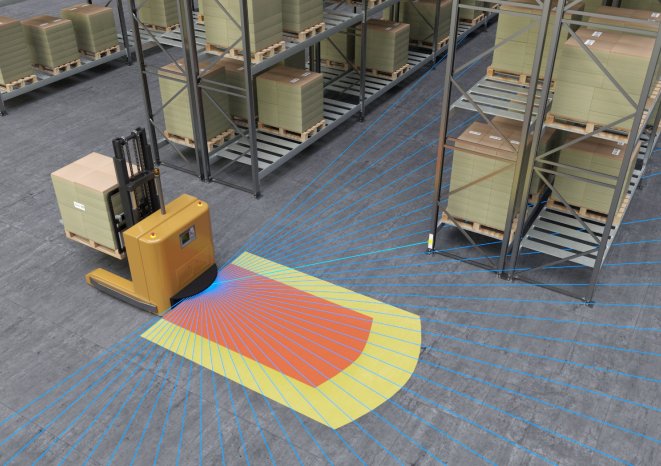

At the LogiMAT, Leuze electronic presented its RSL 400 navigation system - a safe scanner which combines safety technology with qualitatively superior measurement value output in a single device, thereby ensuring reliable AGV guarding and navigation at the same time. Even when using multiple vehicles, these can be controlled collision-free and routes easily adapted. This makes the production system very flexible.

In addition, the OGS 600 enables flexible optical guidance. In production and storage areas, the new sensor enables cost-efficient vehicle automation for the transport of materials and goods. With its edge detection and control signal transmission to the control, the trace can be guided optically, which means that driving can be automated in the simplest of ways. Its compact design and its low minimum distance to the ground of 10 mm means it can be integrated even into flat vehicles. Models with different detection widths and response times cover a wide range of possible applications - also on tight curves and at high speeds, thereby enabling speedy and reliable object detection even under difficult conditions. This guarantees a seamless production process - man and machine are protected.

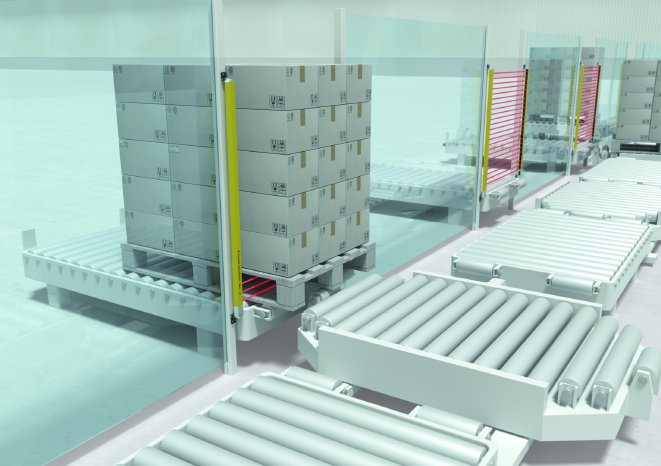

Another Leuze highlight at the LogiMAT was "Smart Process Gating" (SPG) developed by Leuze electronic on the basis of its MLC 530 safety light curtains. This muting process, which functions without the use of signal-emitting sensors, won the 2019 GIT Security Award and has been nominated for the "Best of Industry AWARD 2019" presented by "MM MaschinenMarkt". "Smart Process Gating" makes muting processes for intralogistics, the automotive industry and packaging industry less expensive, simpler and safer. Previously, muting processes with muting sensors were required in order to clearly identify when transported goods are approaching a protective field at material locks and to bridge the passing of these goods through the protective field at the correct moment. As a result of the SPG method developed by Leuze electronic, signal-emitting sensors are no longer needed, which means that conveyor systems can be made more compact. The risk of misalignment or damage to the sensors is therefore eliminated as are the costs for their maintenance and servicing. Furthermore, the purchasing costs, the wiring and risk of manipulation are reduced, which increases the availability of the complete safety device. Particularly in the case of typical intralogistics applications, the height of the protective device is entirely dependent on the safety-related requirements. Synchronization beams do not have to be taken into consideration. With SPG, the first muting signal comes from the process control (PLC), while the second muting signal is generated by the protective field itself. Smart Process Gating requires a detailed knowledge of the process, so that the necessary PLC control signals are made available in the expected time window.

Further interviews gladly arranged on request.