Under the motto ‘Partner in smart surface designs,’ LEONHARD KURZ will be demonstrating its extensive expertise in the home appliances segment when it comes to implementing sustainable, attractive, and customizable surface decorations with integrated smart functions - fully in line with the ongoing trend towards Human Machine Interfaces (HMI) with a closed, seamless surface. “There are hardly any limits to the freedom of design with modern household appliances,” emphasizes Nick Wagner, Head of the Business Area Plastic Decoration Sales and Marketing at LEONHARD KURZ, and adds: “Logos, photorealistic motifs, and customized lettering can now be easily implemented on surfaces and combined with smart sensor technology. Efficient production saves energy and resources, and in line with our Lifecycle Thinking, our decorations have no impact on the recyclability of a component.”

Merging design and functionality

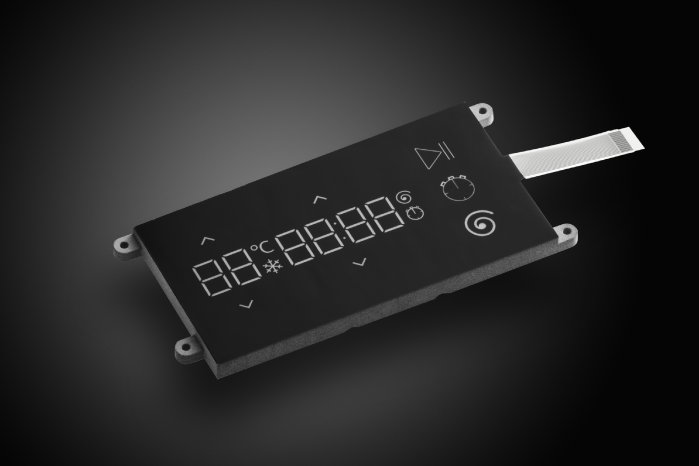

KURZ will be presenting illustrative examples at FAKUMA 2023 in Hall A4 at Stand 4111 - including in the form of two touch-operated washing machine panels. The diverse possibilities of customization and backlighting using IMD technology and In-Mold Electronics (IME) will be shown based on a model with an LCD display and a variant with an LED display. While the black top layer creates a Shy Tech effect with a dark, apparently functionless surface when switched off, the integrated controls only reveal themselves when the user deploys them. This is made possible by the most advanced sensors from KURZ subsidiary PolyIC, which are used both as touch screen sensors in front of display elements and as individual touch key sensors.

In touch key sensors, a diffuser layer can also be cost-effectively integrated directly into the sensor structure. This eliminates the need for light-diffusing plastic inserts for homogeneous illumination of symbols or characters. In addition, the sensor structures are equipped with a light-blocking and laserable decorative layer, for example, to laser in individual symbols or national languages at the end of the process chain and immediately before the panel is installed. By reducing the number of components and work steps, the displays on the operating unit boast an unsurpassed positional accuracy. In addition, the process saves energy and resources.

Attractive and sustainable design options

Using various ring designs, KURZ is demonstrating another option for sustainable and individual washing machine design. Decorated door rings are presented, which are finished with an elegant metallic look using hot-stamping technology.

The finishing enables brand-new effects with a high recognition value and, in contrast to electroplating based on chromium VI, can be implemented not only on full surfaces, but also partial areas. In addition, KURZ metallization saves time and money because the process used is more efficient in production. On the other hand, the chrome hot-stamping decoration allows the use of recycled materials and enables a reduction in CO2 emissions. The REACH-compliant, low-emission, and wafer-thin recyclable metallization is the result of KURZ’s many years of experience in the automotive sector, and now transfers the perfectly customized part metallization to the home appliance industry.

Customization doesn’t stop outside the appliance

With its innovatively designed refrigerator rear panel, the thin-film specialist from Fürth also shows that white goods don’t have to be white all the time and that unique design is playing an increasingly important role in household appliances. Refrigerators are decorated with metallization using an efficient roll-on hot-stamping process. In addition to a brushed stainless steel look, a glossy, matte, or brushed metallic look or light designs are also possible. KURZ will be presenting a total of five different back panel variants at FAKUMA 2023.

With high-quality materials, innovative designs, and advanced manufacturing technologies, the Fürth-based thin-film specialist is able to produce customized and more environmentally friendly surfaces for household appliances, which at the same time meet consumer needs for comfort and functionality. At KURZ, all components come from a single source and are perfectly coordinated with one another. Customers benefit from simplified processes, lower costs, and stable supply chains.

At a glance

FAKUMA 2023 from October 17 to 21 in Friedrichshafen

LEONHARD KURZ Stiftung & Co. KG: Hall A4, Stand 4111

Our trade fair presentation focuses on Automotive, Home Appliances, Sustainability