The South Korean client is a globally renowned battery manufacturer with a substantial market share in both the electric vehicle (EV) and digital battery sectors. It is a key supplier to several world-class automotive and digital product brands.

Enhanced Manufacturing and Design

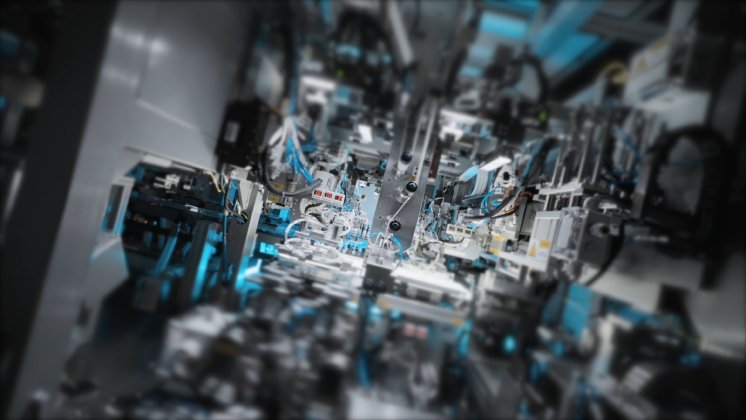

With the collaboration, LEAD has introduced a suite of innovative technologies to comprehensively upgrade manufacturing processes. The integrated cutting and stacking equipment have demonstrated remarkable technical advantages, setting new industry benchmarks:

- Exceptional Manufacturing Precision

- Improved Overall Efficiency

- Streamlined Commissioning

Strategic Partnership Positive Outcome

During production validation, LEAD's integrated cutting and stacking machine has demonstrated outstanding productivity and operational stability. The LEAD team’s optimization capabilities, pragmatic approach, and commitment to technical excellence have earned high praise from the South Korean client, underscoring the value of this strategic partnership.

Batteries play a crucial role in portable, high-performance, and long-lasting digital products. Precision in digital battery manufacturing and equipment efficiency is crucial for improving battery performance, ensuring consumer safety, and reducing production costs.

“Through our strategic partnership with the South Korean client, long-standing challenges in high-precision and technical process control have been resolved, elevating battery performance to the next level,” explained LEAD Chairman Yanqing Wang. “We possess extensive experience in the manufacturing of lithium-ion batteries, allowing us to provide customized solutions for battery manufacturers across various sectors such as new energy vehicles, consumer electronics, and energy management. This expertise enables manufacturers to achieve transformative advancements in efficiency, quality, and technology.”