Label Robotics will participate in LogiMAT 2026, the leading international trade fair for intralogistics, taking place in Stuttgart from 24 to 26 March 2026. With more than 50 years of technological expertise rooted in electronic innovation, the Italian company will present its latest robotic solutions for automated warehouse management and high-density storage.

Founded in 1973 in Limena, near Padua, Label has built its reputation on designing electronic systems that reduce mechanical wear while maximizing reliability. Label Robotics represents the natural evolution of this legacy, combining robotics, artificial intelligence and advanced electronics to deliver highly customized automation systems for modern logistics environments.

Building on over 20 years of proven experience in pharmaceutical logistics automation, Label Robotics has expanded its portfolio to serve a wide range of industries. At LogiMAT 2026, Label Robotics will demonstrate how tailored robotic warehouses can significantly improve efficiency, optimize available space and streamline product handling across sectors including pharmaceutical, e-commerce, retail, food and beverage, and industrial logistics.

Dynamic Store: High-Density Automated Warehouses Built Around Customer Needs

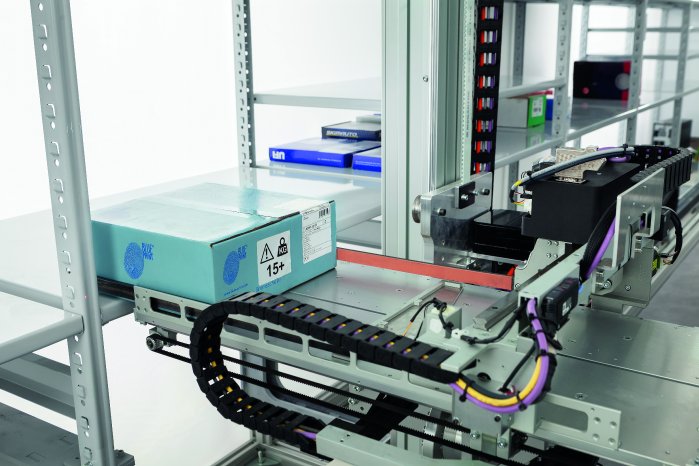

At the heart of Label Robotics' offering lies Dynamic Store, a family of modular and fully customizable automated warehouses designed to manage an exceptionally wide range of products. From standard packages to irregular shapes, bottles, trays, totes and even fragile materials such as glass, Dynamic Store systems are engineered to adapt precisely to the operational requirements of each customer.

Available in multiple configurations (STD, HL, WIDE STD and WIDE HL), all solutions share a common design philosophy focused on maximizing space efficiency, performance and flexibility. The systems handle products up to 80 x 60 x 60 cm in size and 30 kg in weight, with deep shelving enabling high-density storage that can be easily reconfigured to accommodate future needs. Installation heights range from compact configurations to systems reaching up to 16 metres, adapting to diverse facility requirements.

Performance is equally central: depending on the configuration, Dynamic Store can achieve throughput levels of 800-900 packs per hour for picking, 700-800 packs per hour for filling, and up to 10 products per second for high-turnover items when equipped with High Speed modules. These results are made possible by patented robotic arms and independent high-performance channels.

Every system is engineered centimetre by centimetre around the customer's facility, ensuring seamless integration into complex layouts, production environments or space-restricted areas. Lightweight yet robust construction, based on anodized aluminium and premium components, guarantees durability, flexibility and ease of relocation over time.

A Paradigm Shift in Goods-to-Person Automation

At the core of Label Robotics' approach lies a fundamental difference compared to traditional Goods-to-Person systems: the direct management of individual items rather than containers. While most G2P solutions move bins or trays to an operator, who then manually searches for the required product, Label Robotics' systems identify, pick and deliver each single item directly to the preparation or dispatch area. Orders are therefore completed automatically, without intermediate steps or manual picking.

This paradigm shift delivers concrete operational benefits: the elimination of manual picking activities, zero picking errors, faster order fulfilment and full item-level traceability in real time. Orders can be processed in parallel without bottlenecks, while every product is always tracked at unit level, rather than simply being associated with a container.

Advanced Technologies for Hands-Off Warehouse Management

Label Robotics enhances its automated warehouse solutions with a set of advanced technologies designed to deliver maximum autonomy, precision and operational continuity.

Central to this approach is the patented Radar System, which continuously monitors warehouse operations to detect irregularities, prevent collisions and autonomously recover misaligned products without operator intervention. This ensures uninterrupted workflows and a truly autonomous operating model.

Complementing this capability are next-generation pressure-sensitive robotic arms, often described as providing "the sense of touch". Integrated sensors automatically adapt gripping force to each individual product, enabling safe and precise handling regardless of shape, weight or material, including delicate items such as glass containers.

Artificial intelligence further elevates system performance by continuously analysing operational data, recognizing production and expiry dates, and dynamically optimizing processes. Over time, the system learns from real usage patterns, enabling predictive diagnostics, reduced downtime and progressively more efficient warehouse operations.

Automatic Box: Fully Automated Loading

Automatic Box is Label Robotics' fully automated loading solution, designed to simplify and accelerate the inbound phase of warehouse operations. Once products are tipped into the system, Automatic Box autonomously identifies, sorts and stores them within minutes, verifying quantities, dimensions and production data without requiring operator intervention.

Its intelligent architecture is designed to prevent jams and ensure continuous flow, while the integrated accumulation conveyor increases overall throughput by up to 300 additional packs per hour. Built-in intelligence guarantees accurate data handling and traceability, making Automatic Box an ideal solution for environments where speed, reliability and error-free loading are critical.

Seamless Integration with Existing Systems

Label Robotics systems are designed for seamless integration with existing warehouse management infrastructure. Full compatibility with industry-standard protocols, including WWKS2 for pharmaceutical applications, enables straightforward connection to third-party WMS platforms. RESTful APIs and flexible communication interfaces ensure that automation can be deployed without disrupting established workflows or requiring extensive software modifications.

Comprehensive Support and Consultancy

Label Robotics complements its engineering excellence with a strong focus on service and long-term partnership. The electronics-first design philosophy enables up to 98% of issues to be resolved through remote assistance, minimizing downtime and operational disruption.

Support services include 24/7 availability, 365 days a year, with on-site intervention by field engineers within 3 hours across Italy and guaranteed rapid response throughout Europe. Continuous user training is delivered by specialized engineers, ensuring that customer teams can operate and maintain systems with confidence.

Full consultancy services are available, including 3D scanning of customer facilities and comprehensive logistics flow analysis, to design optimal system configurations tailored to each operational environment.

Italian Engineering, Global Vision

All Label Robotics systems are designed and manufactured entirely in Italy, at the company's facility in Limena, Padua. Precision engineering, premium materials and advanced production processes ensure seamless integration, durability and long-term performance in demanding logistics environments worldwide.

With typical return on investment achieved within 18 to 36 months, Label Robotics solutions deliver measurable operational improvements while future-proofing warehouse infrastructure for evolving market demands.

Towards LogiMAT 2026

With its participation in LogiMAT 2026, Label Robotics will highlight how robotics, artificial intelligence and highly customized engineering can transform warehouse automation: boosting productivity, reducing operating costs and creating safer, more efficient workplaces.

By offering fully integrated solutions, from high-density automated storage and high-speed picking to climate-controlled systems and 24-hour delivery points, Label Robotics confirms its role as a key player in shaping the future of intralogistics.

For more information:

Label Elettronica Srl

Viale della Repubblica 18, 35010 Limena (PD), Italy

www.labelrobotics.com