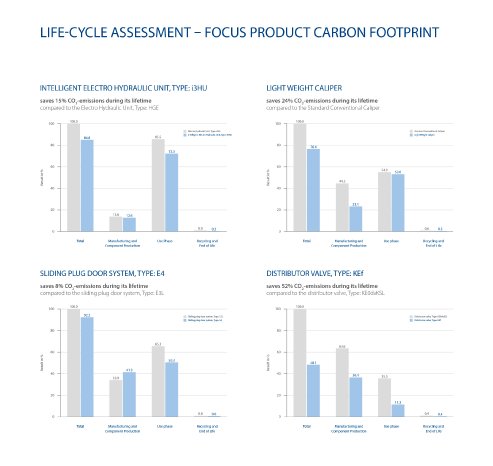

- Carbon footprint of new KEf distributor valve more than halved; CO2 emissions for new light weight caliper reduced by 24%

- Significant reductions in operational emissions for new i3HU electro hydraulic unit and E4 entrance system

- Cross-divisional working group for eco-design

“Environmental protection and sustainability are important priorities for Knorr-Bremse. We are firmly committed to meeting our environmental responsibilities,” says Klaus Deller, Chairman of the Executive Board of Knorr-Bremse and responsible for the Rail Vehicle Systems division. “We are working tirelessly to increase energy-efficiency, cut noise and pollutant emissions, and reduce the impact on our climate and natural resources. Our life-cycle assessments are a demonstration of our commitment to these goals.” Experts analyzed the new Knorr-Bremse Standard Valve (KEf), the new Light Weight Brake Caliper, the i3HU intelligent electro-hydraulic supply and control unit and the E4 entrance system produced by Knorr-Bremse Group company IFE.

The assessments not only include the savings achieved when products and systems are in operation but also during their manufacture and end-of-life recycling or disposal. “We comply with the requirements set out in the ISO 14040 international standard for life-cycle assessment and the UNIFE Product Category Rules. This means that our analyses all have a demonstrable scientific basis,” adds Stefan Bräuherr, responsible for Corporate Responsibility at Knorr-Bremse.

Reduced materials requirements during manufacture or greater operational efficiency

In the case of the Knorr-Bremse Standard Valve (KEf), the reductions in CO2 emissions are particularly impressive. The company’s leading distributor valve for freight vehicles was subjected to a fundamental overhaul that resulted in its carbon footprint being reduced by more than half (52%) compared with its predecessor. In the case of the Light Weight Caliper – a new brake caliper designed for weight-critical applications – the carbon footprint has been reduced by almost a quarter (24%). As both systems operate without using power themselves, Knorr-Bremse achieved these reductions largely through an ingenious design that cut the volume of materials required. As a result, fewer resources are also needed for maintenance, with a corresponding reduction in the environmental impact.

In the case of the i3HU intelligent electro-hydraulic supply and control unit, with which Knorr-Bremse has simplified the task of integrating hydraulic braking systems into LRVs, its operational efficiency plays a prominent role in the 15% reduction in emissions that has been achieved. And the carbon footprint assessment of the E4 entrance system manufactured by Knorr-Bremse Group company IFE, (as installed, for example, in DB AG doubledecker passenger cars) reveals a CO2 reduction of some 8%. This latter case demonstrates the importance of taking a differentiated approach to life-cycle analyses: The carbon footprint for manufacture of the E4 is actually a little higher than its predecessors, but its lowenergy operation and the efficient use of materials during maintenance more than compensate for this.

In line with the requirements of the ISO standard, the impact of weight-reduction on actual operational efficiency was not taken into account when calculating the carbon footprint. This means that operators will benefit from additional savings: In the case of the light weight caliper, for example, use on a standard metro vehicle over a period of 40 years could be expected to save some 10 MWh of energy per caliper. “Reducing the environmental impact of our products is a long-term affair at Knorr-Bremse,” emphasizes Bräuherr: “In 2017, with the aim of embedding product sustainability even more firmly in the development process we also set up a cross-divisional working group on eco-design in which colleagues from Corporate Responsibility work closely together with representatives of the Rail and Truck divisions, for example from the remanufacturing sections.”

Focus on industrial remanufacturing of products

Extending the life of a product has a huge impact on sustainability, which is why industrial manufacturing has always been an important focus at Knorr-Bremse: This involves refurbishing used products so that they can continue to function as before, albeit with a somewhat shorter operating life. Compared with a newly-manufactured part, the overall impact assessment is more favourable, as the requirement for new materials and consumption of energy are considerably reduced. In the case of remanufactured compressors, actuators (block brake units, brake cylinders, caliper units), distribution, load-related and weighing valves, only the wearing parts of brake components are replaced by Knorr-Bremse, and well over 90% of the material is reused. In 2017, Knorr-Bremse remanufactured some 45,000 products of various kinds at its Service Center in Berlin. In China in the same year, braking equipment for more than 2,000 high-speed railcars, 1,700 locomotives and almost 1,500 metro trains was remanufactured, as were some 1,000 high-speed train entrance systems, 1,500 HVAC units and around 16,500 actuators.