Kaeser’s cutting-edge measuring technology delivers the ideal solution. With advanced process data acquisition, businesses can lower energy costs and sustainably enhance compressed air quality. High-precision sensors track all key process and energy metrics, including leakage currents, voltage quality, pressures, temperatures, and flow rates. Additionally, leaks, pressure dew points, differential pressures, and internal machine conditions are fully transparent - providing operators with invaluable insights and significant operational advantages.

Continuous monitoring

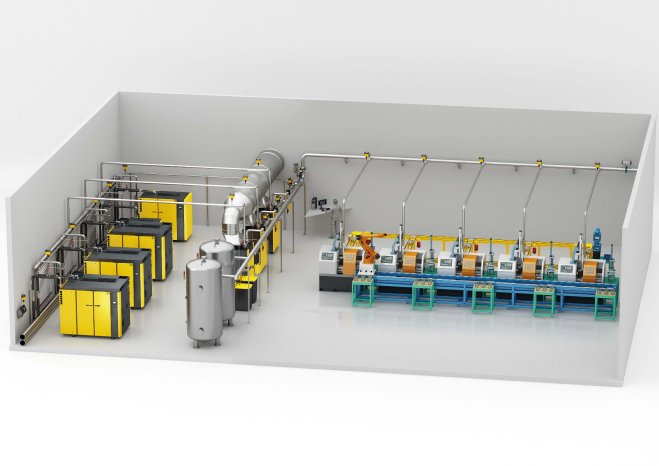

Advanced measuring technology enables continuous monitoring of the entire compressed air system. Data can be captured, analysed, and visualised in real time. Kaeser multi-sensors transmit key measurements directly to central control units, such as the Sigma Air Manager, providing the foundation for future predictive maintenance. This proactive approach cannot only reduce costs but also significantly lowers the risk of unplanned downtime.

Placing the right sensors in the right locations is essential. Intelligent sensors capture multiple data points at each measuring location and integrate seamlessly via the secure Kaeser Sigma Network. This advanced process data acquisition enables real-time monitoring, detailed analysis, and valuable system insights for fault prevention and process optimisation. Operators can fine-tune their compressed air systems independently or benefit from real-time monitoring by external experts.

With state-of-the-art sensor technology, modern measuring devices are compact, powerful, and energy-efficient, ensuring reliable operation even in hard-to-reach places. They are also easy to install and ready for immediate use.

Maximum efficiency and sustainable savings

Reliable compressed air supply is essential for seamless production. Kaeser’s advanced measuring technology delivers precise data to optimise system settings, detect leaks, and efficiently manage compressed air distribution. This enables compressed air station operators to reduce energy costs, prevent unnecessary downtime and maximise overall production efficiency.