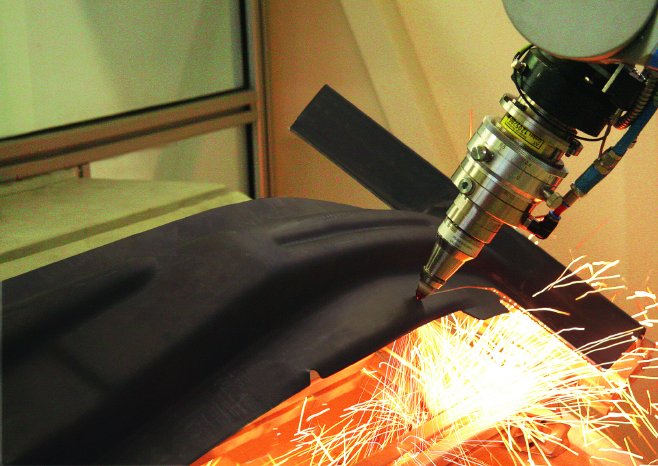

The system concept of the JENOPTIK-VOTAN® BIM series is based on a beam guide inside the robot. This allows using laser sources with a power of up to 4 kW without having to use a complex external beam guide. At the same time, the equidistant beam path prevents the laser beam from pumping effects, ensuring a stable beam quality. This approach allows Jenoptik to deliver its customers a technological competitive advantage.

With its metal cutting laser machine series, Jenoptik serves the automotive industry by cutting e.g. complex car body and structural parts as well as hydroformed tubes, being used for exhaust systems or car body rail manufacturing. JENOPTIK-VOTAN® BIM is simple to integrate into production lines or combined processing units.

Watch a live demonstration of the robot at Jenoptik’s booth 6087 in Hall North 2 at the FABTECH trade show in Chicago, IL USA from November 9 to 12.