The latest surface inspection systems often require a great deal of time to initially install and as a result can be extremely costly. Typically, pri-or to actually classifying the defects, they must first be categorized and the parameters must be defined. Manual parameter tuning can often-times take weeks or months to complete, and even the best results are not able to optimally convey whether defects are 100% reliably detect-ed or if there are a minor number of false positives. In contrast, ISRA Parsytec's automatic system tuning requires only a few short minutes to enable a "best-in-class" defect search with only a minimum number of defects.

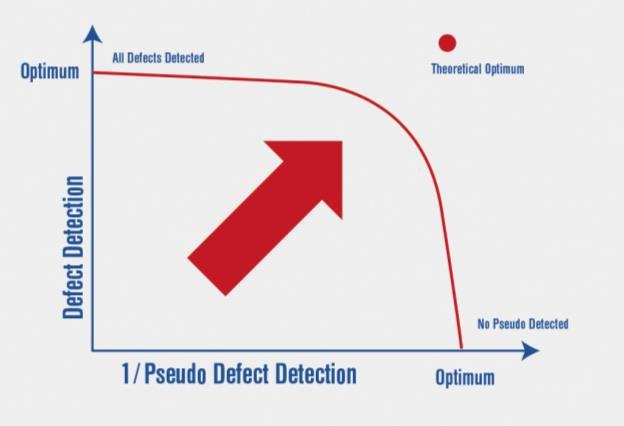

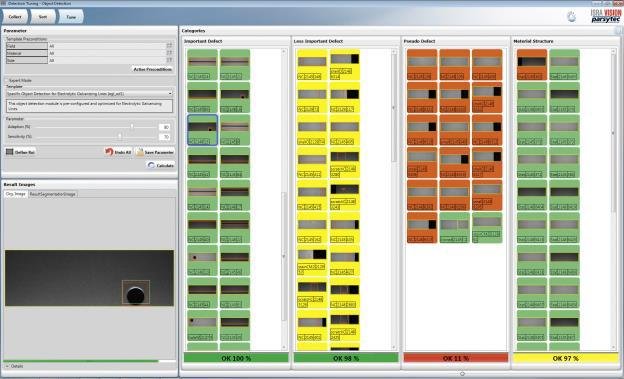

With thousands of installations worldwide ISRA VISION Parsytec has already performed at customer's locations. Fast Tuning technology is equipped with a pre-installed set of defect classes, increasing the speed of implementation and initial installation considerably. Once the relevant defects have been marked, the system is able to find all com-parable defects on its own and all that the user needs to do is confirm them. Usually, at this point categories are broken down into four classes: critical defects and those of less significance, false positives and material structures. The "classifier" created in this manner now calcu-lates various optimal solutions and offers a selection of first-class clas-sifier set-ups. Because no defect detection can offer one single perfect solution, but instead several good options, the optimization task is solved using the Pareto principle, applying this unique method. Fast Tuning is able to automatically account for the complex dependencies between each of the individual parameters, a major step forward com-pared to previously used methods.

Parameters are optimized automatically based on the four categories using approximately 50 attributes for each individual defect. Automated algorithms are far superior to the manual process, in particular when the purpose is to find the best possible operating point in a 50-dimensional space, allowing defects to be ideally assigned.

Fast Tuning is the latest example of how ISRA VISION Parsytec, the global market leader in surface inspection, continues to come up with even more sophisticated automated methods to achieve the best sur-face inspection results faster than ever before. In addition, metal manufacturers benefit from the significantly simplified handling and the lightning-fast set-up times of the inspection systems, reducing the re-turn-on-investment to a minimum of the service life.

About the company

ISRA VISION PARSYTEC AG is the world's largest supplier of surface inspection systems in the metal industry: 18 of the top 20 steel manu-facturers make use of ISRA products. With more than 540 installations around the globe, customers not only benefit from an advanced sur-face inspection system, but also receive reliable and comprehensive information about the relevant surface defects on all production levels. The innovative EXPERT5i software solutions allow the customer to prepare customized surface quality and yield management applications while integrating surface quality data with process data.