This project will investigate the potential to increase the performance of Friction Stir Welding (FSW) tools by using advanced coatings deposited by Ionbond’s PVD, CVD and PACVD processes. In particular it will be testing coatings deposited by the latest variant of PVD – HiPIMS (High Power Impulse Magnetron Sputtering), which Ionbond is also evaluating in a large European funded project (LifeLongJoints – see www.lifelongjoints.eu) and for use in commercial applications. Partner MERI is a world leader in research into HiPIMS coatings and technology and will be using the process to deposit inovative new coating materials and structures.

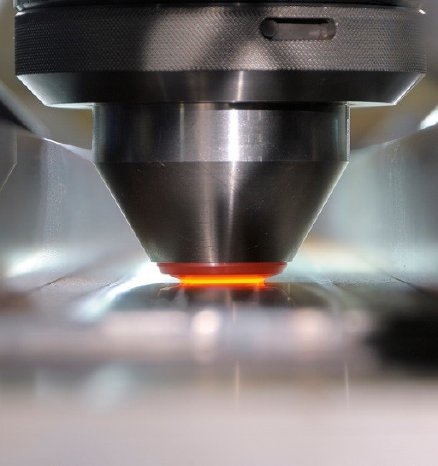

Friction Stir Welding (FSW), which was invented by TWI, is an innovative joining process using a rotating, non-consumable tool, which is traversed along the interface of two work-pieces. The process typically provides enhanced weld quality, strength and durability together with reduced energy consumption and environmental impact when compared to conventional fusion welding processes.

However, FSW tooling works in an extremely demanding environment – high temperature (>700 °C), high abrasion and exposure to the reactive effects of freshly exposed metal surfaces – this has limited its commercial application to low melting point alloys, principally aluminium.

Through the application of advanced coatings, we hope to enable the welding of ‘high-temperature’ materials, such as steel and titanium for high-value industries (e.g. Aerospace & Transport) as well as improving the surface quality of welds in aluminium and other alloys.

www.ionbond.com

For more information please contact info@ionbond.com