The abbreviation ‘HP’ in the acronym LBHP stands for ‘high performance’ and relates not only to the high performance of the new modular bar lights. The state-of-the-art high-power LED technology and optimised power electronics mean the lights reach brightness levels of 120,000 lux in continuous operation and even up to 1 million lux in strobe mode. These impressive figures are ‘concealed’ inside a compact aluminium profile that is not only lightweight, but also flexible in terms of its configuration. Illumination lengths can be individually selected in 100 mm increments, leading to rapid and cost-effective availability as there is no need for specific designs or made-to-order production. The modular concept allows the creation of very long lighting systems with a light field length of up to 4 metres. As a result, extremely large test objects, such as car body panels or sheet material can be illuminated uniformly using just one lighting system, even from large working distances of over one metre.

Flexibility thanks to optical accessories

Another advantage of the new LBHP series is the ability to adapt the lighting flexibly to the relevant application using optical accessories such as lens arrays, diffusers and polarisers. This allows precise control of the light angle and targeted illumination of the test area. Lens arrays, for instance, can be used to gradually reduce the beam angle of the LEDs from 150° to as little as 16° in order to guarantee optimum focussing of the light on the desired distance. Diffusers, polarisers or a combination of the two can also be used, depending on the nature of the surface to be inspected. The selection of different wavelengths from blue (470 nm) to infrared (850 nm) supports a high-contrast representation of the test criteria and therefore reliable evaluation. This adaptability guarantees a reliable solution even for demanding inspection tasks.

Robust and compact – for industrial applications

In addition to flexibility, the lighting design also relies on compactness and light weight, thus facilitating the mechanical integration of the LBHP series – even when there is limited space or rapidly moving processes. Both the rear groove profile and the front mounting holes can be used for mounting. Swivel mounting is also possible using the mounting bracket. Despite their compact size, the bar lights can withstand industrial conditions. The IP50 protection can be extended to IP64, if required. Configurations with IP69K protection will be available for the food and pharmaceutical industries at a future date.

Tried and tested technology for easy integration

In addition to the new mechanical concept, the LBHP series also incorporates tried and tested expertise, such as the standardised M16 connection concept and the integrated controller technology for easy electrical integration and reliable operation in continuous/switch or strobe mode. Owing to extremely short flash times (10 to 750 µs) and brightness levels (up to 1 million lux), this guarantees inspection independent of ambient light without motion blur. Logistics processes, for example, even in the case of large portals, can be carried out reliably.

Practical application in a pick & place task in the field of e-mobility

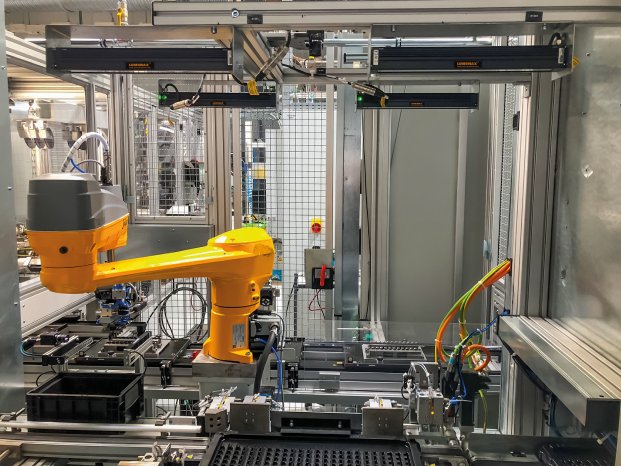

One example of the successful use of the new LBHP series is the partnership with Schaeffler. For over 75 years, the Schaeffler Group has been driving forward pioneering inventions and developments in the field of motion technology. Innovative technologies, products and services in the fields of electromobility, carbon-efficient drives, chassis solutions, Industry 4.0, digitisation and renewable energies make the company a reliable partner for making movement more efficient, more intelligent and more sustainable – across the entire life cycle. The motion technology company produces precision components and systems for drive trains and chassis as well as rolling and plain bearing solutions for a wide range of industrial applications. Through its Special Machinery department, Schaeffler has a network of 14 locations worldwide where product solutions are brought to fruition. One of these locations is in Bühl and specialises in manufacturing solutions for the manufacture and inspection of components and systems for the electromobility sector, in particular rotor and stator production.

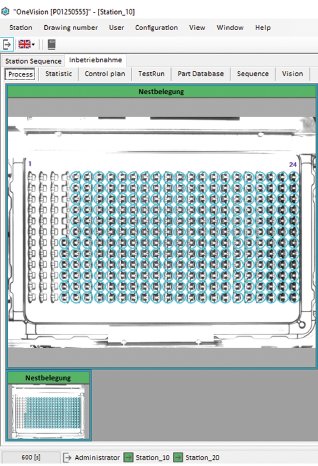

In this specific case, the aim was to optimise a highly automated manufacturing plant for stators. The image processing system used was intended to support a robot in precisely removing and placing individual parts from a blister pack. The blister packs measuring around 400 x 600 mm are delivered to the individual manufacturing stations fully automatically using automated transport systems. First, the robot positioned at the respective station fills the blister pack with parts. Here, the camera checks whether the pockets in the blister pack are empty and contain no remnants from previous parts. The machined part can then be placed in the pocket. During the pick and place process, the robot receives continuous information about which pockets are still available for filling. Second, the robot removes the relevant prefabricated objects. The purpose in both cases is to successfully introduce the manufactured parts into the further manufacturing process.

The main aim was to maximise the efficiency and precision of the ‘pick & place’ process by enabling the robot to remove several individual parts from the blister packs at the same time and introduce them correctly into the production line. A completeness check using an image processing system is essential here. It has to be ensured that all required parts are present in the packaging in the correct position and quantity. Even one missing or incorrectly positioned object can adversely affect the entire manufacturing process and lead to delays. This is unacceptable, especially in high-frequency manufacturing processes. In addition, a repeated completeness check is required as there are several interventions along the line.

The structural conditions in the plant represented a further hurdle in the implementation of the image processing system. Due to the space required by the robot, a working distance of around 120 cm needed to be maintained between the camera, lighting and blister packs. This presented the engineers with an additional challenge, as lighting solutions generally lose intensity and uniformity with increasing distance. A high-performance solution was therefore required that would provide sufficient and uniform illumination, even over long distances, and could be integrated into an existing production line without taking up too much space. At the same time, the system needed to remain adaptable and cost-efficient in order to be able to respond quickly to changing requirements.

Another problem was the instability of the blister packs. These are made of thermoforming film and tend to deform slightly during transport and storage. This led to undesirable illuminated surface reflections under direct lighting that made image analysis considerably more difficult. This was particularly problematic in the case of the black parts to be inspected. These offered little contrast to the blister pack material, which was also black. In this particular case, the exact angle of incidence of the lighting was also crucial for a satisfactory object image.

Solution thanks to powerful and compact LBHP bars

To meet these complex requirements, Schaeffler Special Machinery opted for the new LBHP series from LUMIMAX®. Four powerful infrared beams, each 300 mm long, are used to illuminate the blister pack area. The infrared lighting offers several crucial advantages in specific applications: Firstly, it enables uniform and high-contrast illumination of the inspection area – even at a working distance of 120 cm. Secondly, its invisible radiation prevents unwanted reflections on the uneven surfaces of the blister packs.

In addition, a daylight suppression filter was also used on the camera system to ensure that the image processing system works reliably even in strong ambient light, such as hall lighting. Optimum test conditions were created in combination with a special infrared filter, which is precisely matched to the wavelength of the lighting used.

As already mentioned at the start, a key advantage of the LBHP series is its modular and compact design, making it possible to adapt the lights to the available space and tasks. Thanks to the modular design, the number of lighting units required could be reduced from the original six to four, which saved costs. Despite the lower number of lights, the light output is still uniform.

Measurable efficiency gains with LBHP Bar Lights

In summary, the new LBHP Bar Lights from LUMIMAX® play a crucial role in fulfilling the demanding testing requirements at Schaeffler Special Machinery. Thanks to their high flexibility, high performance and compact design, the bar lights were able to successfully overcome the challenges posed by the large working distance, difficult lighting conditions and limited space. The reduction in the number of lighting units and integration into the existing manufacturing process led to a significant increase in inspection efficiency and precision, whilst at the same time optimising costs.