- The granulators of the SB series (patented) will play a central role. In bottle or pre-shredded plastic waste recycling, it is now possible to save up to 30 % of energy compared to conventional granulators: the material to be size-reduced is directly conveyed to the grinding chamber with the help of load-controlled feeding screws. With conventional granulators, the material has a chance to escape continuously bouncing on top of the rotor not allowing the knives to seize it effectively. A considerable amount of the drive capacity is consumed by an unnecessary acceleration, friction and deceleration. A forced feeding device for the material is responsible for providing the rotor with an optimum amount of material per time unit.

- The drying of plastic waste at the end of a washing/separation line shows a considerable potential for saving energy; to an even higher degree by optimizing centrifuges, the mechanical spinning off of surface humidity can be achieved and therefore the changing of the state of aggregation of water - a process consuming a lot of energy - can be omitted (with rigid plastics and bottle lines) or reduced to a minimum. Downstream thermal drying units are no longer fuelled by electricity but by gas.

- Refitting and retrofitting of existing plants is an important subject. Herbold's experienced technicians will assist and consult you utilizing their vast experience gathered in the construction of more than 300 manufactured washing and separation plants.

- For processing extremely large waste plastic pipes up to a diameter of 3 m HERBOLD MECKESHEIM has designed a new shredder impressing by its price/performance ratio: the pipe shredder of the HOS series with an oscillating size-reduction surface is capable of shredding extremely large pipes with lengths of up to 6 m in one single step.

- A new machine concept with a vertical rotor shaft has been developed for pulverizing: in this field as well, the main focus has been on energy saving and on a more efficient pulverizing process to transform the material into powder as the desired end product. The PU 650 pulverizer is one of the first design sizes with drive capacities between 75 - 90 kW for throughputs of up to 1 t/h.

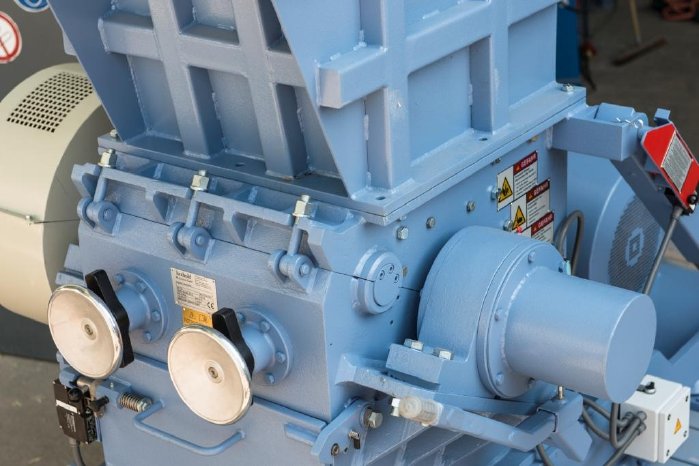

- In many cases of size reduction, customers opt for a one-step solution: heavy duty applications require very high drive capacities. Due to a revision of the granulators of the SMS series, their overall stability has been reinforced, paving the way for extremely complicated heavy-duty applications, such as massive semi-finished products but also for contaminated plastics and tires, containing foreign bodies.

HERBOLD MECKESHEIM in close collaboration with the customers find tailor-made solutions in their technical laboratory, currently being considerably extended, in Meckesheim nearby Heidelberg. A first trial with customer's original material is free of charge; procession is executed on machines according to a normal industrial production scale.