Higher quality and efficiency in post-processing of high-pressure die-casting components, Friction Stir Welding for aluminum components for electro mobility combined with a high automation competency: at the Euroguss from January 14th till 16th, 2020 in Nuremberg, Grenzebach presents a wide product spectrum of solutions to the visitors (hall 8, booth 331).

Friction Stir Welding for E-mobility

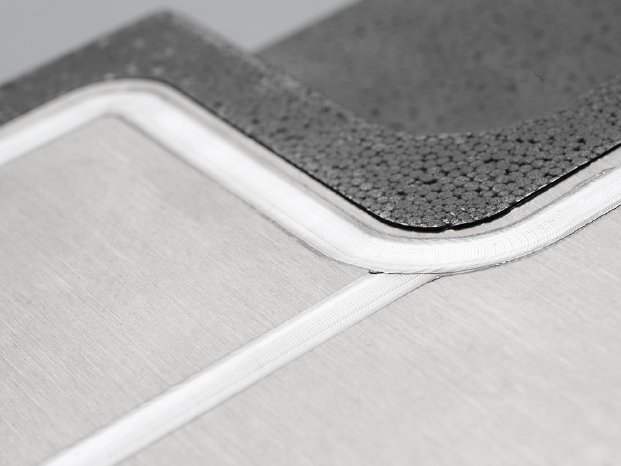

During the Auto Summit in Berlin early November, politicians, association representatives and industry members once more emphasized their commitment to electro mobility. New mobility concepts, such as traveling with “green” electric power, have a direct impact on the development of casting components. “We observe an increased demand for welding of die-cast components in the automotive industry, such as the manufacturing of battery trays or heat exchangers for electric vehicles. This is where our Friction Stir Welding solution can make a difference”, says Sahin Sünger, Product Manager for Friction Stir Welding at Grenzebach. Commonly, this involves work with cavity-prone die-cast parts with uneven surfaces, which is extremely difficult to do with conventional welding technologies. This is where Friction Stir Welding makes the difference. A rotating tool generates the required process heat at the seam with friction and pressure. The material becomes plastically deformable with the heat applied and is stirred along the joint with the rotation of the tool.

Scalable solutions focused on efficiency

The FSW technology enables the production of durable and media-tight weldings. Since Friction Stir Welding is a solid state joining technology no pores or hot cracks are generated. Exactly these effects are very common to conventional fusion welding. Grenzebach stands for scalable FSW solutions for serial production. The double spindle FSW gantry units of the D-DSM series provide two independently working welding heads. “With this innovation, our customers can reduce their effective cycle time. Besides the dynamics and the welding speed, the quick loading and unloading of the machine are critical for cycle time and economic efficiency. Our customers can benefit from our expertise of numerous successful projects”, says Sahin Sünger.

Aluminum still on the rise

The FSW technology more and more complements the foundry technology, also due to the fact that aluminum substitutes steel! The automotive and aviation sector count on lightweight components; in mechanical engineering, aluminum ideally withstands mechanical stresses. “The quantity of processed aluminum in vehicle bodies increases every year. Especially in the automotive industry changes are under way. That is why support our customers with the use of FSW technology and the development of new products offering consulting services and sample weldings”, says Sünger.

Complete added value of casting parts

Grenzebach is also a partner for the efficient manufacturing of classics, high-quality pressure die casting parts. The company collaborates with various foundries and has a supply chain of different molding procedure products. Milling, lathe turning, drilling: Grenzebach handles all processing steps for casting parts. In the machining center at the Grenzebach location in Jiashan, China, a full CNC and multiple-axes machine park is available. Grenzebach uses all painting procedures for casting parts available for the surface treatment. The automated Grenzebach paint-shop stands for high-quality results. Grenzebach processes more than 10.000 tons of die-cast parts per year. The casting parts are used in special machinery of automation industry, such as industrial robots or machine tools. “For high-quality industrial die-cast parts our experts developed a particular passion. We work individually on mould and model construction and together with the customer develop casting parts – always focused on the optimized serial production. Grenzebach stands for short lead times and additional added value”, says Thomas Liu, Head of Casting at Grenzebach.

With VR glasses right into the middle of the action

The extensive automation competency of Grenzebach as well as the many years of experience as sparring partner for innovation projects was well received by visitors to the Grenzebach booth. The way how complex processes can be intelligently organized and how Grenzebach is able to ensure an optimum material flow between printers, saws, furnaces and finishing systems was made visible to visitors with the use of VR glasses. Right there in Frankfurt - a trip into the factory of the future.

Rigorous occupational health and safety standards

A well-organized process chain in additive manufacturing helps relieve employees from ergonomically unfavorable working conditions. “The more industrial 3D printing will be integrated into our daily work, the more important rigorous occupational health and safety standards will become. From the very beginning this was a key topic for us – for users, legal certainty and proper control of potential risks play a major role”, says Oliver Elbert. Authorities, such as the Federal Environment Agency note that employees can be exposed to fine dust and nano particles in the post processing of 3D printing components. The use of automated handling and transport technology contributes to the safety of the company and its employees.

Intelligent use of 3D printing data

In additive manufacturing data is especially valuable for production. To secure information from the individual value creation stages and to facilitate analysis and consistent conclusions, SERICY provides the ideal basis. The digitalization platform was developed in-house at Grenzebach. Oliver Elbert: “The demand to intelligently control the high-end procedure of additive manufacturing and to develop further with data analysis, was evident at the formnext”. This shows that Grenzebach hits the nail on the head with its wide range from project consultation to manufacturing of Automated Guided Vehicles and supply of a digitalization platform, performing dynamically and improving daily.

More Information about FSW technology:

- Grenzebach, as an experienced system integrator and supplier of Friction Stir Welding equipment, delivers turnkey FSW process solutions for industrial serial production.

- The highest quality is provided by the DynaSTIR tooling technology from Grenzebach, which reduces the process forces up to 50 percent compared to conventional FSW tools and thus enables gentle component processing. Furthermore, the heat input is lower. Therefore, less distortion arises and the components remain dimensionally stable.

- The Grenzebach FSW experts are pleased to assist you with technical discussions of your specific joining concepts. Even during the design phase of the components, Grenzebach supports with a FSW specific design of assemblies.