Thanks to its modular design, media-resistant materials and precise adjustment options, the 493 series fulfils all the requirements of modern industrial applications - especially where safety, compactness and reliability are required under extreme operating conditions.

Design I - compact, light and flexible

Design I was specially developed for applications where limited installation space, low temperatures and a lightweight construction are crucial. It is the preferred solution for use in diaphragm compressors for hydraulic protection - for example when compressing hydrogen or helium in sensitive energy and environmental technology systems.

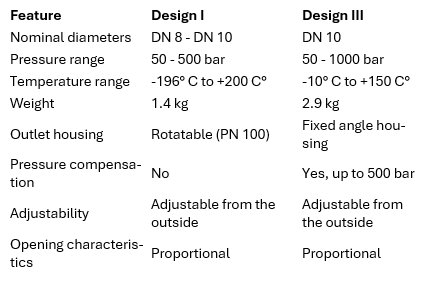

With a temperature range of -196° C to +200° C, a pressure range of 50 to 500 bar and a weight of just 1.4 kg, the valve variant is ideal for cryogenic and mobile applications. The rotatable angle housing (PN 100) allows flexible alignment of the medium and simplifies integration into complex pipework schemes. The externally adjustable pressure setting and proportional opening characteristics offer precise control of the pressure level. Important: Design I is not back pressure compensated, which offers a design advantage in systems without back pressure loading.

Design III - robust, powerful and back-pressure compensated

In contrast, Design III was designed for applications with high back pressures and increased system loads - for example in high-pressure pumps, gas liquefaction systems or industrial storage systems for hydrogen, nitrogen or CO₂. The valve has a back pressure-compensated design (up to 500 bar) and is therefore particularly suitable for systems with unstable back pressure ratios or cyclical load changes.

The valve variant covers an extended pressure range of 50 to 1000 bar and works reliably in the temperature range from -10° C to +150° C. The fixed angle housing ensures maximum stability in continuous operation, while the external adjustability and proportional opening characteristics enable precise adjustment of the pressure level. With a weight of 2.9 kg, Design III is significantly more robust - ideal for stationary and large industrial systems.

Central areas of application for both designs

- Diaphragm compressors in hydrogen technology, helium compression and industrial gas processing

- High-pressure pumps up to 1000 bar - e.g. in CO₂ extraction, water jet cutting technology and the chemical process industry

- Cryogenic systems (e.g. LNG, cryogenic gases) with special temperature and media compatibility requirements

- Secondary circuits in the food, pharmaceutical and beverage industries (CIP/SIP, cooling and heating systems)

- Pressure relief in modular systems where flexibility and ease of installation are crucial

https://www.goetze-group.com/de-de/produkte/baureihe-493

https://www.goetze-group.com/en/products/series-493

https://www.goetze-group.com/de-de/produkte/technische-gase-entdecken/ueberstroemventile/493-s181283.html

https://www.goetze-group.com/en/products/technical-gases/overflow-valves/493-s181283.html