The SKZ Plastics Center is now offering participants in selected classroom courses a supporting web-based training (WBT) free of charge for up to 4 weeks after the end of the course. After the classroom course, participants automatically receive access authorization to a thematically appropriate e-learning course. This profitable offer is now available in the subject areas of materials, compounding and extrusion, quality assurance and injection molding.

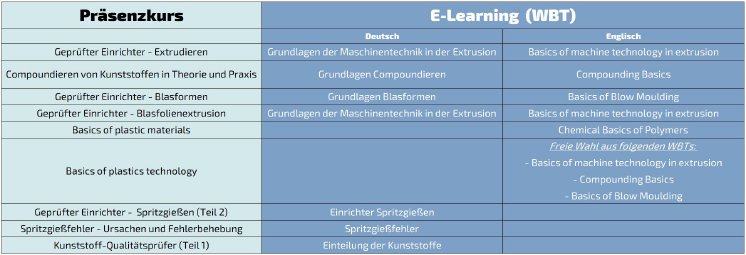

Variety of e-learning options in German and English

Plastics quality inspector course participants receive access to the e-learning module “Classification of plastics”, for example. Participants in the “Certified Setter - Extrusion” course receive access to the e-learning module “Fundamentals of Extrusion Machine Technology”. The WBT “Fundamentals of Compounding” is made available to the “Compounding of Plastics” course, while the online self-study course “Fundamentals of Blow Moulding” is included in the booking for participants of the “Certified Setter - Blow Moulding” course. WBTs in English such as Compounding Basics, Basics of Blow Molding and Basics of machine technology in extrusion are also available for the classroom courses in the areas of materials, compounding and extrusion. Especially for participants whose native language is not German, the English-language e-learning formats are an ideal supplement to consolidate what they have learned at their own pace after the classroom course. In the area of injection molding, the classroom courses “Certified setter - injection molding” and “Injection molding defects - causes and troubleshooting” are supplemented with the corresponding WBTs.

Further classroom course-WBT combinations are already being planned in order to continuously expand the range of courses on offer and optimally adapt them to the needs of the industry.

Face-to-face and digital course combination for optimum learning success

With this new offer, the SKZ is creating flexible and practical qualification measures that meet the modern requirements of the plastics industry. Companies benefit from specialists who can build up in-depth knowledge in a practical, face-to-face training course and can also flexibly access specifically tailored training content after the course to acquire further knowledge and skills or to deepen and refresh what they have learned.

“We are proud to be able to offer such a modern training program and to support companies in the plastics industry in the further training and qualification of their specialists,” says Matthias Ruff, Head of Sales Education and Research at SKZ. “The combination of online and classroom training optimizes the learning process and promotes the sustainable qualification of skilled workers.”

Web-based training - flexible learning for the plastics industry

Blended learning is the ideal solution for anyone who wants to learn flexibly, self-taught, from any location and according to their own schedule and learning speed. Interactive features such as tests, quizzes and videos make learning effective and engaging, allowing learners to apply their knowledge directly and receive immediate feedback.

Online placement test: find injection molding course according to your own level of knowledge

The complex processes and settings of an injection molding machine require precise technical knowledge. Gaps in operating knowledge can have serious consequences - from production rejects, material waste and increased costs to possible damage to the machine or tool. Trained specialists can not only avoid errors, but also increase production efficiency. With the new online assessment test, interested parties can obtain a quick and precise assessment of their specialist knowledge with a course recommendation in the field of injection molding.

“Through the placement test with course recommendation, we enable prospective course participants and companies to efficiently select the appropriate injection molding course and thus obtain a needs-based qualification and sustainable further training,” says Irena Heuzeroth, trainer for injection molding and additive manufacturing at SKZ.

Click here for the injection molding placement test