Machine vision methods have been widely used in industry for many years - particularly in quality control and automation. With the increasing use of AI-based analysis methods, even highly complex applications can be realized today. However, this still requires the targeted selection of suitable illumination setups and the optimal choice of acquisition parameters.

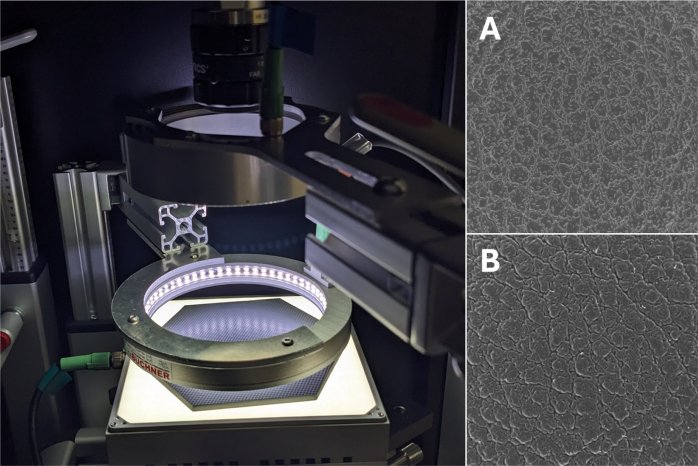

Since early 2025, the Spectroscopy working group at SKZ KFE gGmbH has been operating a new camera inspection system that enables a wide range of variable lighting situations - even in combination with several types of light. The large measuring chamber, which is primarily used to shield external light, houses a high-resolution monochrome camera. In conjunction with a selection of high-quality, quick-change lenses, the smallest structures below 50 µm can be captured and analyzed in great detail with a large field of view (approx. 100 x 100 mm²).

Four different types of illumination are available, which can be used for a variety of inspection tasks - such as the detection of defects (e.g. scratches, cracks, streaks, inclusions) in injection-moulded components or granulates as well as for surface characterization:

- Diffuse incident light illumination:

For uniform illumination of opaque samples from above. - Flat-angle/dark-field illumination:

Flat incident light is scattered at elevations or depressions, making fine structures and defects on dark or matt plastic surfaces visible. - Dome illumination:

Diffuse light from all directions ensures shadow-free visualization of shiny or structured surfaces. - Transmission lighting:

For examining transparent or translucent materials such as amorphous or thin-layered, uncolored plastics (e.g. films).