At present aromatic hydrocarbons are mostly produced through petrochemical processes. They are generated in a steam cracker or fluid catalytic cracking unit during the production of ethylene, and typically contain the compounds benzene, toluene, ethylbenzene and xylene. This mixture is known as BTEX, or the aromatic fraction. Based on these substances, and using a variety of chemical reactions, a broad spectrum of compounds can be produced, which in turn can be used to fabricate medicines, plastics, paints and numerous other products we use on a day-to-day basis.

In the light of fossil fuel depletion, the increasing difficulty of accessing remaining reserves and the decreasing quality of the raw materials extracted, research is urgently needed. So-called "drop-in" solutions are of particular interest: here new raw materials can be processed using existing production lines, to manufacture end products identical to those already available on the market. This accelerates the market implementation of the new product and reduces investment to a minimum.

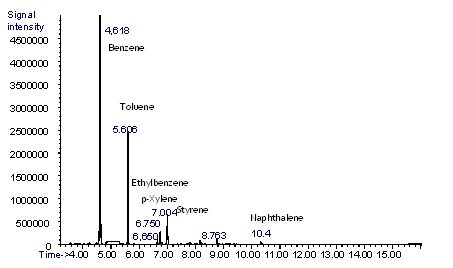

The mixtures produced using the Fraunhofer ICT's newly-developed process contain numerous aromatic compounds, as shown by a chemical analysis: "The chemicals in the product mixture are mostly benzene, toluene, ethylbenzene and para-xylene, but there are also significant quantities of styrene and naphthalene," explains Jochen Forstner, the project leader. Gaseous by-products include hydrogen, alkenes and alkanes, which are also important in economic terms. They are the initial raw materials needed to fabricate further chemical products, such as plastics and medicines, and are in increasing demand. Using the new process developed by the Fraunhofer ICT, many of the future challenges faced by the chemical industry as a result of the increasing scarcity and price of raw materials can be solved.

Background information:

The research is based on special mixtures of fluid salts in which cracking reactions can be carried out. The initial compounds are introduced into the liquid salts, and the reaction generating the products takes place at 400°C in the presence of a catalyst. The reaction in the liquid salt produces a hot vapor which is cooled outside the reactor. This leads to the condensation of the aromatic compounds. These surprising reactions can be attributed in part to catalytic effects, but thermal decomposition is also thought to play a role. As the results are very recent, there are still many open questions, according to the research team.

This discovery will facilitate the chemical use of sustainable raw materials and also the use of plastic wastes. The Fraunhofer ICT is engaged in intensive research on this topic.

The institute has been working for over 10 years on the sustainable and resource-efficient fabrication of chemical products. Other research topics include for example the production of high-value products from wood-industry waste, thus disposing of contaminated materials. Several research projects also concern the modification of sustainable raw materials, enabling them to be processed directly into plastics and end products, or into bio-based building blocks for polyethylene and polypropylene.