At the same time, Advanced Pulse Control ensures precise adjustment of pulse duration and frequency. This enables high-quality marking of metals, plastics, semiconductor components, and even sensitive materials while minimizing heat input and maximizing energy efficiency.

A particular synergy arises from the combination of Multi-Level Marking and the optional vision system. The integrated IMP (Intelligent Mark Positioning) system is enhanced by automatic focus adjustment, delivering not only a crystal-clear image at every focus distance but also a positioning accuracy of up to 40 µm. This enables camera-guided part alignment, reliable pre- and post-mark verification, and real-time validation—ensuring error-free results even in highly complex applications.

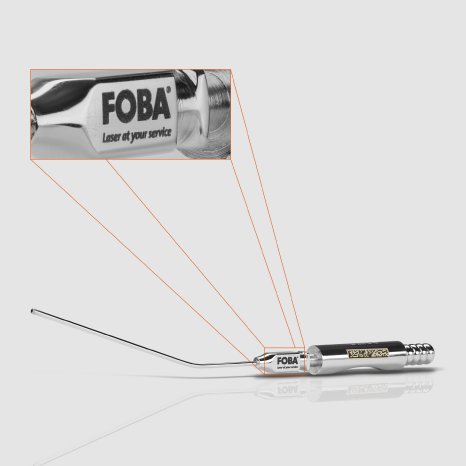

“With the NextGen Y-Series, we are bringing a solution to the market that combines maximum flexibility with outstanding marking quality. In doing so, we support our customers in making their production processes more efficient and future-proof. Over the coming years, we will continue to implement additional features to make the new generation of the Y-Series even more powerful and valuable for our customers,” says Philipp Febel, Director of Product Management, Marketing & R&D at FOBA.

The NextGen Y-Series thus combines innovative technology with a clear focus on quality, efficiency, and sustainability – ensuring reliable and cost-effective marking throughout the entire product lifecycle.