The M3000-UV is a 2 watt uv-laser stand-alone marking station with optional integrated camera. This system completes the existing range of wave lengths in the M-series as an addition to the well-established fiber-laser based systems. The UV laser is most appropriate to mark sensitive material as it creates only low heat level. The range of applications includes materials like silicone, HDPE, PET or PVC.

Thin multiple layers of lacquer on translucent plastics can be accurately removed by precisely tuned fiber lasers. The so called day-night-design creates brilliant color effects for best legibility in all lighting conditions, and also creates characters and symbols that can be backlit in the dark.

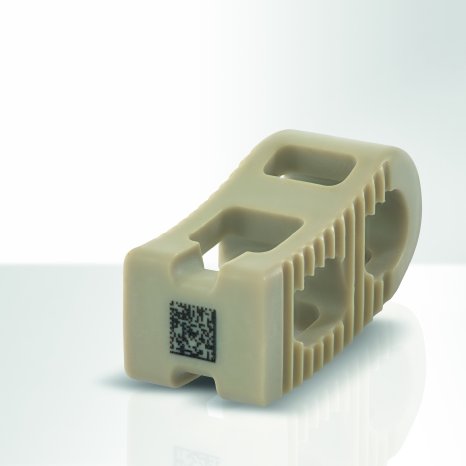

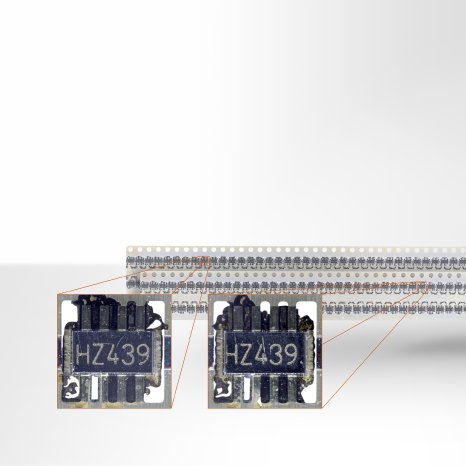

Manufacturers also use laser marking to ensure long-term traceability of a plastic part throughout its complete product life cycle and also to optimize logistics processes. Also, when markings are embedded in the plastic layers, products are protected against counterfeiting.

FOBA’s marking systems with integrated camera enable pre- and post-inspection of parts and marking results, as well as providing exact alignment of the marking relative to the position of the product. This can prevent cost intensive marking errors and scrap can be reduced by up to 80 percent. Beyond that, an automatic autofocus, easy to operate via FOBA’s marking software MarkUS, can significantly speed up set-up time.

At the Fakuma, FOBA’s stand number 2112 will be in hall A2, showcasing the marking systems M1000 and M2000. Visitors will get the opportunity to experience vision-based laser marking on plastic show samples.

Alltec GmbH | FOBA Laser Marking + Engraving