With the Basic control variant - for MIG/MAG standard, MMA and TIG (LiftArc) welding as well as for air arc gouging, welding voltage, wire-feed speed and non-latched/latched operation can be set via the twin-knob operation on the wire feed unit.

The Synergic version with its single knob operation on the wire feed unit offers not only the additional forceArc® process and the brand new root welding process, rootArc®, but also a selection of preset JOBs (welding tasks). With both versions, the operator can switch processes, set parameters and check data on the machine's display.

These control variations have no electronics in the wire feed.

With Basic and Synergic in the "S" version, the control electronics, operating elements and displays are integrated in the wire feed. This allows direct access to all welding parameters and data directly at the workplace. In addition, the Synergic S variant allows 16 welding programs to be called up via the torch.

With is powerful, directionally stable arc, forceArc® reduces production costs by up to 50 percent and provides for deep penetration and virtually spatter-free seams of the highest quality.

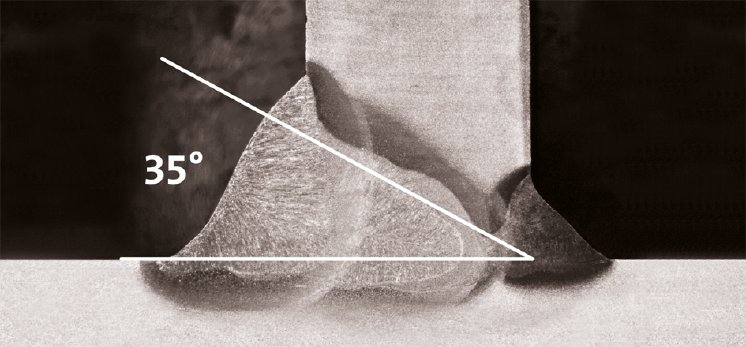

rootArc®, another innovation from EWM research, is characterised by a stable, soft, short arc with considerably less spatter tendency than with standard short arcs: ideal for simple and reliable root welding, for easy bridging of seam gaps and positional welding - with all sheet and pipe wall thicknesses, in all positions, even without pool backing. Even if the welding leads exceed the intended length in practice, the highly dynamic inverter technology means that the good joining characteristics of the Taurus remain unchanged.

The 3-in-1 casing combines power source, cooling module and transport vehicle in a single unit. This ensures simple transport and easy handling (mobile, can be lifted by crane and moved by fork lift). Sophisticated air cooling delivers greater cooling output and therefore long duty cycles, while minimising soiling inside the machine.

Other benefits include reproducible ignition and welding results, quick access to the joining process and a stable welding arc irrespective of the length of the intermediate hose package, the mains lead and fluctuations in the electricity supply. The ingenious cooling system featuring an especially effective heat exchanger and a large 12-litre tank provides for a "cold" torch at all times, even with high ambient temperatures.

The three "decompact" Taurus power sources are joined by the compact Taurus 301, which is only available as a gas-cooled model, with a performance of 300 amperes and an integrated wire feed optionally equipped with Basic or Synergic controls in the unit.