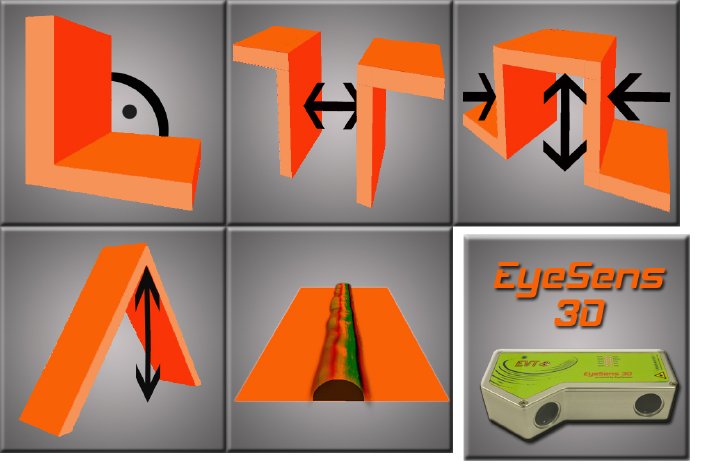

Therefore, with the integrated software commands, the EyeSens 3D makes the control of e.g. bent iron components during the production process easier. The components are inspected for their exact bending angle or the clearance.

In addition the sensor can be used to scan the surface of e.g. iron sheets in the automotive industry. The surface is then used as reference for defining the first cutting height. With the command for height control, the laser line keeps the tension during the entire process of cutting to e.g. control the blowpipe for the precise cutting height.

The command for the inspection of adhesive and sealing beads calculates the state of the adhesion by scanning automatically the adhesive bead contour, width, gap width and inspects the course of the adhesive bead application. Even for complex sealing beads the EyeVision software offers a high volume of preciseness.

The EyeSens 3D is based on the EyeSpector 3D hardware and the EyeVision image processing software. With EyeSens 3D the software runs on the 3D camera. The inspection programs for the visual inspection are put together via the drag-and-drop function of the graphical user interface of the EyeVision software. The different commands are visualized via small icons, which can be dragged with the mouse into a command list, the so called "program editor". Finally these commands are executed one by one by the software.

The EyeSens 3D has a scan rate of up to 400 Hz and is equipped with a laser of protection class 1 with a wave length of 635 nm and 5 mW power. The sensor has 2 inputs and 4 outputs as well as 100 Mbit Ethernet.