The functional principle of an air vane motor is simple: An air vane motor consists of a rotor, which revolves in an eccentric cylinder. The vanes are pressed against the outside of the rotor wall by centrifugal force and build working chambers. The compressed air expands in these working chambers; pressure energy is converted into kinetic energy and the rotor turns.

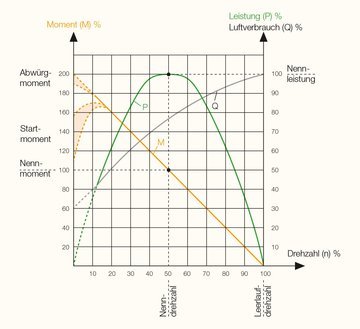

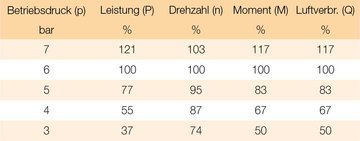

The air motors are characterised by their speed adaptation feature, which adjusts automatically according to load variations. When load is removed the air motors run at idle speed. If low load is conflicted, when there is low torque on the motor spindle, the working speed approaches the idle speed. The working speed is reduced as soon as the torque increases. At 50 % of the idle speed the air motor achieves its maximum power. "This is also the optimal working range of the air motor. In the range of 40-50 % of the idle speed the air motor works particularly energy-efficiently. This is a criterion which we consider carefully during motor design", explains the DEPRAG Product Manager for air motors Dagmar Dübbelde.

If the theoretic calculation for the application is too complex, a practical test with an existing pneumatic motor, hydraulic or electric drive, grinding or drilling machine can be offered. If the technical data for the machine is not known this can be comprehensively determined using the innovative freely programmable performance test stand at DEPRAG. As well as the performance, the speed and torque, it is also possible to measure operating pressure and air consumption.

The performance test stand functions within a measurement range of up to 500 Nm and up to 12,000 rpm in four-quadrant operation. The DEPRAG engineers can carry out a comprehensive determination of power up 22 kW and create customer-specific characteristic curves of load profiles. In addition, as many load cycles can be programmed as are required. Each test item can travel individually on three axes and the system can be flexibly adjusted to the test item. In the test laboratory at DEPRAG, analysis can be carried out simply and in the shortest possible time. With their comprehensive performance analysis service feature, DEPRAG SCHULZ GMBH u. CO. are the preferred solution provider for the selection of drives systems relating to customised applications or the test of existing drives.

Performance calculation

If the required working speed and torque for the application have already been determined the optimal drive can be designed. Using the formula: working torque divided by 9550 you can calculate the theoretically required power in kW. This then needs to be adapted to the framework conditions of the application, such as smaller cross-section openings, the available operating pressure or oil-free operation.

Operating conditions affecting performance

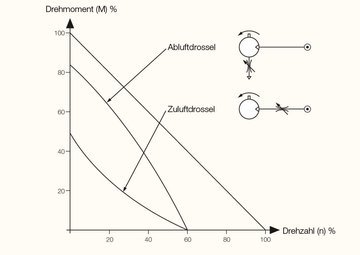

The speed can be simply and flexibly reduced through regulation of the air supply. Depending on application environment, there are two options for this: exhaust air throttling or supply air throttling. Exhaust air throttling reduces the speed of the motor without noticeably reducing the power or torque of the air motor. A throttle valve keeps exhaust air back and creates a counter pressure which in turn reduces the speed.

If you want to reduce the speed of the air motor and also the power or torque, then you would be well advised to also use supply air throttling.

As well as the regulation of the air supply the speed can also be reduced via operating pressure. The technical data of the DEPRAG air drive is based on an operating pressure of 6 bar. If the application however only has 5 bar directly available at the motor, then the motor loses 23 % of its power. If only 5 bar is available, the motor power is reduced by 45 %. Each DEPRAG air motor can be operated between 4 and 6.3 bar in order to regulate the speed and torque. A reduction in operating pressure is a good option if the air motor is too powerful.

Another influencing variable is oil-free operation: The optimal life span and performance of an air motor is attained using 1-2 drops of oil per 1 m³ air consumption. If operating without lubrication an additional loss of power of 10-20 % should be factored in.

Defining rotational direction

Motors which are only designed for operation in one rotational direction are more efficient than reversible motors. Pneumatic specialists determine the rotational direction by looking from the air inlet to the motor shaft. This is exactly opposite for electric motors: here the rotational direction is specified by looking at the motor spindle.

Next a suitable motor is selected for the application including any desired external materials (such as stainless steel, cast iron, ceramic, aluminium or others). These then need to be integrated into the individual design. DEPRAG offers various spindle varieties and individual fixture options. You can find a wide range of air motors with integrated planetary, worm or spur gears in the DEPRAG motor programme. If the application requires additional safety features, there is the option of an additional holding brake. Brake motors can be found in the manufacturer’s programme. For use in potentially explosive environments there are even motors available with the required ATEX certification. Technical inspection of the maximum permissible axial and radial load of the drive spindle of the air motor completes this integration.

Air motors are extremely high performance, robust machines with a long lifespan. The longest possible performance life of the drive can be ensured by compliance with the framework conditions determined at the time of design and stated in the operating instruction manual of the individual machine. The framework conditions include adherence to the recommended air quality, lubricated operation, compliance with maintenance intervals, maximum length of the supply hose of 3 metres and sufficient cross-section openings of the supply hose and connection fittings.