Applications

Poraver® is an excellent lightweight aggregate and filler for a wide variety of refractory products and can be used similar to vermiculite or expanded shale respectively clay (ESCS - Expanded Shale, Clay and Slate).

Unshaped (monolithic) products

- Heat resistant lightweight concrete

- Insulating mortar

- Backfills

- Gunning mixes

- Ramming mixes

- Insulating fills

- Moulded parts from refractory lightweight concrete

- Insulating concrete parts

- Insulating panels

- 7 different grain sizes from 0.04 mm to 4 mm allow the composition of a sieve line with a dense structure

- The density can be specifically adjusted by selecting different grain sizes and very good thermal insulation properties can be achieved

- The spherical shape, low weight and high compressive strength of the Poraver® grain make it easy and safe to process the mixes

- Compared to many other lightweight fillers, Poraver® offers low water absorption, which reduces the water requirement of the mixture and therefore achieves high strength

- Poraver® offers a constant material quality and chemical composition - ensuring consistent quality of the finished products

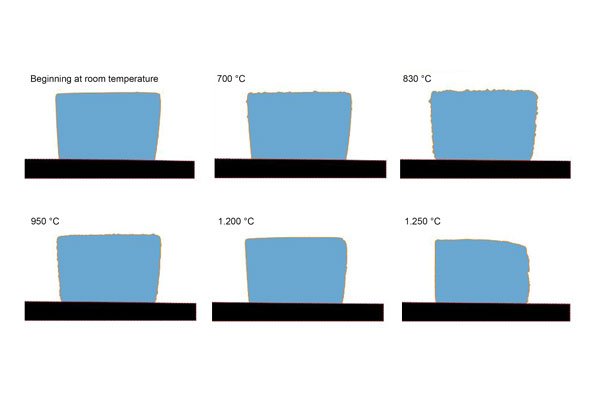

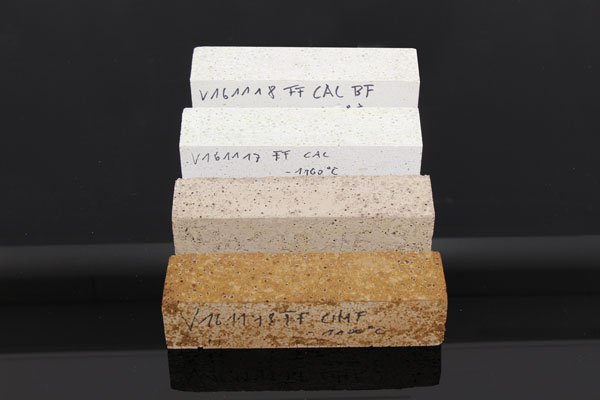

In the following trials Poraver® was tested in hydraulically hardening, unshaped (monolithic) and insulating refractory lightweight concretes. The material properties were tested on a pourable mixture for a firing at 1,000 °C.

Conclusion

The measurements on the tested system clearly show that the technological properties of the product are within the desired range even after the firing at 1,000° C. The flexural strength of the mortar, after firing, corresponds almost to the value of the initial test and the compressive strength is approximately 1/3 lower than before the test. The remaining longitudinal shrinkage of the system of -0.8 % is within the acceptable range.

Guide formulation for lightweight refractory concrete as PDF

Request our guide formulation for refractory concrete without obligation. Simply contact us via the following form. We will send you the information immediately by e-mail.