- Custom ultrasound height sensors increase efficiency and durability

- Combined module easier to install than individual components

- Lower weight reduces fuel consumption

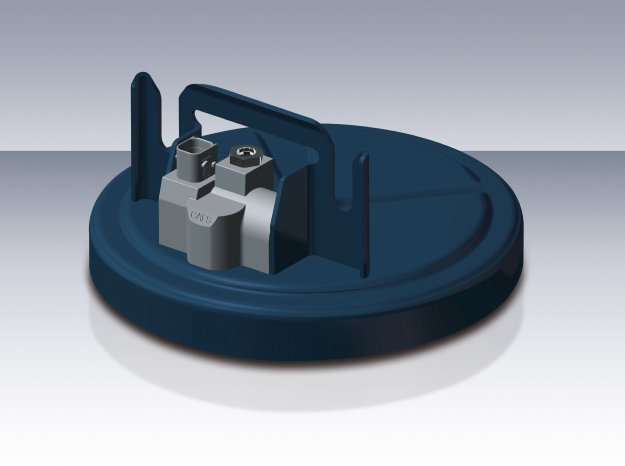

For priority use in trucks, ContiTech brings a new air spring module to market. The new Continental Air Spring Leveling System (CALS) will regulate the vehicle level with an ultrasound sensor and integrate valve function for filling and bleeding right at the air spring plate. "With CALS, we're taking the air spring module in a whole new direction," says Diethelm Bauch, segment leader of ContiTech Air Spring Systems. "It brings ultrasound technology into a fully integrated system - with plenty of advantages for our customers."

All electronic and pneumatic elements of CALS meet the latest technical standards and offer vehicle operators greater efficiency. During development, ContiTech worked closely with specialists from Continental Automotive. Alternatively, we can combine CALS with a Continental control device and thus give our customers a complete, closed system for commercial vehicle level regulation," explains Bauch. The wear-free, extremely precise ultrasonic height sensor implanted in the module replaces the currently common mechanical height sensor, which has rods that are prone to failure. The latest generation of this sensor can easily be adapted to various air spring designs and axle types just by replacing the software.

When filling and bleeding the air spring, a directly controlled solenoid valve allows maximum strength and compactness. "A version with a precontrolled solenoid valve is also planned, so that even large quantities of air can enter through the valve for short vehicle lifting times and minimal pneumatic loss," says Eckard Neitzel, head of product development and commercial vehicle original equipment at ContiTech Air Spring Systems.

Easy installation and lower weight

CALS even greatly simplifies the vehicle layout. Instead of several individual parts, just one module is used, which takes up considerably less space. At the same time, the system will further reduce the number of electrical lines and connections in the vehicle. These two changes ease assembly on the vehicle production line and lower the logistical cost compared to several individual parts. Still another advantage: At the same time, CALS lowers vehicle weight significantly. On a truck with a trailing axle, it can save more than 3.5 kg per vehicle. The lower weight also reduces fuel consumption: On a 400,000 km stretch, it saves more than 20 liters.

Right now, the Continental Air Spring Leveling System is still in the development phase. Mass production is planned by 2017.