Coherent shows at the BLECHEXPO 2015 some intelligent technologies for metal processing applications:

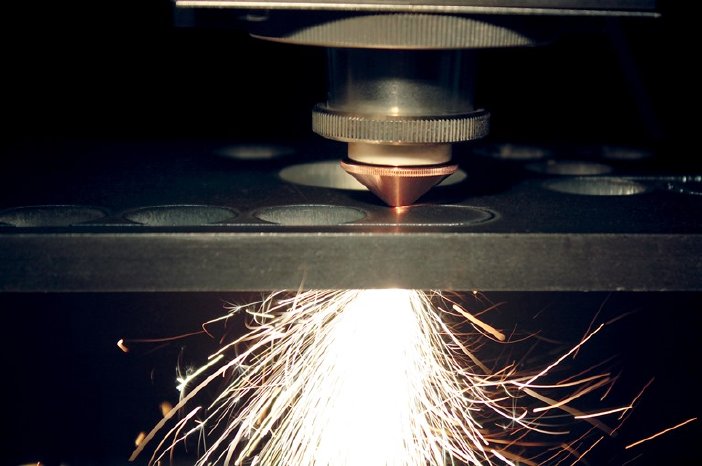

The HighLight FL-Fiber Lasers are OEM fiber lasers that delivers 1-4 kW of continuous-wave fiber-coupled output at 1 µm wavelength. The lasers consists of individual laser modules, which contain field proven pump diodes and a proprietary non photodarkening active fiber. The diodes, fibers and optics are designed and manufactured in house. The vertical integration enables Coherent to design components such that the final product is delivering optimal performance and reliability at minimal cost of ownership. The output power of each fiber laser module is combined using a proprietary optical combiner. HighLight FL lasers at all power levels are available with a range of output delivery fiber options optimized for cutting and welding of a broad spectrum of metals and alloys and is covered by an industry first BRIGHT warranty. This Back Reflection Immunity Guarantee provides assurance of Higher Throughput and lower cost. This multi-kW fiber laser platform is ideal for cutting mild & stainless steel, copper, brass and aluminum with excellent quality and is designed for field serviceability. The modular architecture and remote diagnostics combined with Coherent’s factory service training program and worldwide support infrastructure enables OEM customers to directly provide service to their end customers.

Coherent’s experienced global logistics and service network supports customers with remote warehouses and trained field service engineers all over the world.

Coherent has extended its integrated laser machine tool offering with the META platform featuring faster cutting speeds and better positioning repeatability. META offers an industrial type controller and new software with multilingual software interface. META will be equipped with Coherent Laser sources cutting metal and non-metals.

The HighLight 10000D is a high power, direct diode laser system that produces 10 kW of output, with free space beam delivery. This preserves the inherent brightness of the diode laser source and enables the use of an optical system with a large (275 mm) working distance. The HighLight 10000D outputs a line beam, with a wide range of length options, ranging from 6 mm to 36 mm. Together, all these factors translate directly into enhanced laser capabilities in industrial processing applications. Specifically in cladding, it yields a higher material deposition rate (greater than 10 kg power per hour), allowing the laser to cover large areas in a short amount of time. Similarly, in heat treating, it enables processing of larger areas in a single pass. In addition to high performance, a variety of options are available with the HighLight 10000D to enhance ease-of-use. These include an air knife, which protects the laser from back-splattered material, heat and returned laser light, thus extending system lifetime. A pyrometer for monitoring work surface temperature enables closed-loop control of laser power during heat treatment and cladding. Features to enhance productivity include a laser system control unit with a simple graphical interface, and remote diagnostics that allow system operation to be analyzed by Coherent service personnel over the internet.