With a PCB for a micro-light, ANDUS impressively proves that electronic modules do not always need to be big. The double-sided board with several vias is only 50 µm thick. The PCB’s diameter of 0.8 mm (approx. 1/32“) is about the diameter of a drawing pin.

Currently, there is a strong trend towards PCBs that partly assume the thermal management of the module by using thick copper layers, massive copper or aluminium as the head distribution media. As many of these technologies and applications are not yet common knowledge, ANDUS is currently strengthening its training and education efforts.

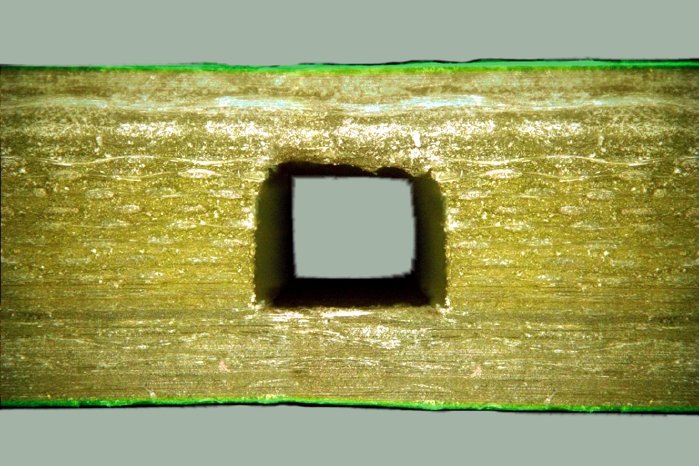

A further example of the special designs created by ANDUS is the company’s PCR reactors (PCR is the abbreviation for Polymerase Chain Reaction). The biochemical sequencing of polymers is a temperature-dependent process: The faster the temperature cycles get, the more efficient the analysis becomes. ANDUS have developed a special PCB for this application that is able to store high quantities of heat over a very short time in a 3 mm (approx. 1/8“) wide copper sheet. Semiconductor-based micro-peltier elements are directly applied to this copper sheet and provide the enormous heat flows required.

In medical and/or biochemical applications, copper-free electronics is an important topic as this standard material in PCB manufacturing is cytotoxic and thus can not be used in systems with biologically active substances. Therefore, ANDUS has developed a process that replaces copper on sensor and actor electrodes by aluminium or stainless steel. As the company has a long-term experience in the area of flexible PCBs, ANDUS is able to realise flexible printed circuits with conductive tracks from stainless-steel.

A further, biocompatible alternative to copper is gold. ANDUS uses this metal for its Microflex adapters for brain research: Two foil straps with a width of 1 mm (approx. 1/24“) are used to contact a total of eight parallel signals. The contacts are gold-plated and only 60 µm wide.

ANDUS also manufactures x-ray ionisation detectors for image-guided medical and industrial analytics in PCB technology. Furthermore, simple capacitive sensor structures can easily be structured on PCBs in most cases. Thus it is possible to combine the sensor and the interpretation electronics on the same PCB. Today, this technology is used for the capacitive measurement of humidity in tissue or when measuring conductivity or electric potentials. However, the technology can also be used in diagnostics and even cosmetics applications.

More information can be found on the Internet: http://www.andus.de