Entrance East, Booth EO91A

The high-tech company CeiliX is building on last year’s world premiere at LogiMAT 2026 and showcasing the next stage in the development of overhead automation. The focus is on the transition from a single SkyBot to a fleet. For the first time, two SkyBots can be seen operating simultaneously in a coordinated setup at LogiMAT, demonstrating how automation can be scaled from individual workstations to larger production and warehouse areas.

At the booth, live demonstrations of the SkyRunner and the SkyBots will be shown in two configurations: one with a robotic arm and one with a scissor gripper. Two SkyBots operate in coordination, making the interaction of multiple overhead systems visible.

Platform Logic for Different Tasks

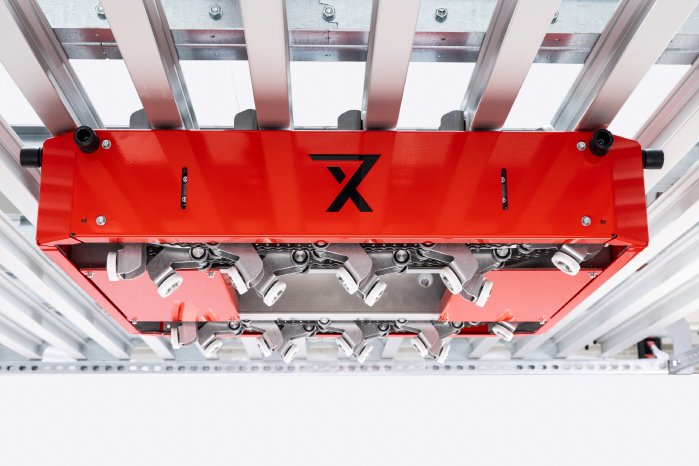

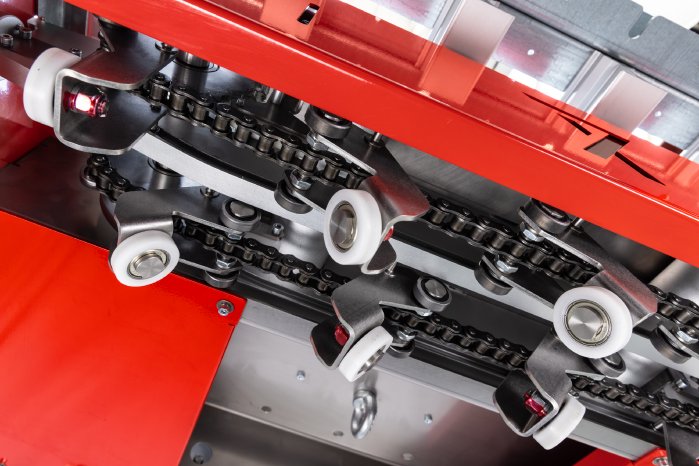

CeiliX follows a clear platform logic. The SkyRunner is the overhead vehicle and forms the basis for a low-threshold entry into automation. Depending on the application, the appropriate tool is mounted to it. At LogiMAT 2026, CeiliX is presenting the SkyBot in two variants: one with a robotic arm and one with a scissor gripper. For additional applications, the SkyRunner can also be equipped with other tools, such as a hoist. The key point is that the base remains the same, while the function is defined by the automation task at hand. This allows automation to be expanded step by step, from individual tasks to covering multiple stations within an operation.

Scalable Overhead Automation

What CeiliX announced as the next development step at LogiMAT 2025 can now be experienced live in operation this year. The multi-patented CeiliX technology enables the parallel operation of multiple systems overhead. The foundation is a modular, ceilingmounted rail system on which the overhead vehicles (SkyRunner) move, forming the basis for scalable automation.

The rail system can be installed quickly, adapted flexibly to any space using a modular approach and easily expanded as requirements grow. This flexibility is exactly what enables many companies to take their first steps into automation. This also applies to production environments with columns, machines and organically grown layouts, where floor-based solutions often reach their limits.

Relief for Teams and a Pragmatic Entry into Automation

CeiliX demonstrates how challenges that shape everyday work in logistics and production can be addressed through overhead automation. These include, above all, relieving employees when loads become too heavy, structural pressure from skilled labor shortages and unnecessarily complex manual process steps. The focus is no longer on a single application, but on an approach that can be expanded modularly. For users, this means processes can be automated without tying up additional floor space or rebuilding existing layouts.

Mathias Entenmann, CEO and co-founder of CeiliX, says: “Since we celebrated our world premiere here at LogiMAT a year ago, we keep hearing the same thing from our customers: getting started with automation using our technology really is that simple. They are particularly convinced by the flexible modular system that can grow along with their needs.”

CeiliX at LogiMAT: Live Demonstrations and Expert Discussions

Visitors to LogiMAT 2026 can experience firsthand at the CeiliX booth, Entrance East / Booth EO91A, how CeiliX brings scalable automation to the ceiling. The CeiliX team will be available for expert discussions and individual consultations.