Hall 8, Booth 8B41

Due to rising energy prices and more stringent CO2 pricing, companies are more than ever required to further reduce their CO2 emissions. When manufacturing its aluminum profiles, Bosch Rexroth starts with upstream CO2 emissions and uses raw materials with a reduced product carbon footprint (PCF) of 5 kg CO2eq/kg aluminum. This is almost 50% less than the average value for primary aluminum used in Europe. In the long term, the company intends to reduce its CO2 footprint by increasing the recycling rate and making efficient use of secondary aluminum. Customers can thus reduce the carbon footprint of their products and benefit from future-proof components and stable supply chains.

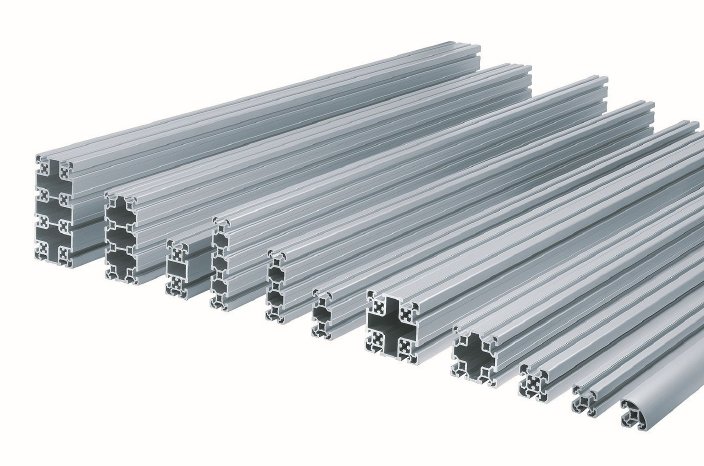

Bosch Rexroth offers the world’s largest selection of aluminum profiles. For more than 40 years, they have been enabling custom-fit and efficient solutions for machine frames, safety fences, ergonomic workstations and lean material supply.

Since the end of 2025, the company has been using raw materials (billets) with a reduced product carbon footprint (Scope 3 upstream) for profile production: The billets have a PCF of 5 kg CO2eq/kg aluminum, which is almost 50% less than the average of 9.7 kg CO2eq/kg aluminum for primary aluminum used in Europe (European Aluminum, Environmental Profile Report, Nov. 2024). In a typical assembly workstation with a width of 1000 mm, a depth of 600 mm and an aluminum content of 34.3 kg, 161 kg of CO2 can be saved with the Low Carbon Aluminum Profiles. With ten workstations, this corresponds to savings of 1.6 t CO2.

In the long term, Bosch Rexroth intends to further reduce the PCF value of the profiles by increasing the recycling rate and making efficient use of secondary aluminum.

Greater transparency in the CO2 footprint

On request, Bosch Rexroth not only provides the cradle-to-gate PCF (from raw material extraction to the factory gate) of its aluminum profiles, but also the PCF values of over 300,000 other standard components. Customers can use this to calculate the PCF value of their own machines and plants.

Visitors to LogiMAT can obtain information about aluminum profiles at the Rexroth booth B41 in hall 8.