This commitment to sustainability, in addition to product stewardship, environmentally friendly manufacturing processes and modern recycling procedures also entails long-term company development as well as multifaceted social involvement. In 2010, for the sixth time in a row, the BMW Group was named the most sustainable automobile manufacturer in the world by the Dow Jones Sustainability Index.

Efficient Dynamics is the guiding principle in all areas of vehicle development. The main pillars of this strategy include the continuous increase in the efficiency of internal combustion engines, the further development of BMW ActiveHybrid Technology, innovative concepts for electric mobility and the long-term use of renewably generated hydrogen as an energy source, as well as intelligent lightweight construction technology and the optimisation of aerodynamic vehicle characteristics. At the BMW Group Innovation Day 2011, the latest innovations and concepts representing the underlying ideas of Efficient Dynamics particularly well will be presented, from the development areas of internal combustion engines, BMW ActiveHybrid, electric mobility and lightweight construction.

Sustainability by commonality: the new BMW Group Efficient Dynamics family of engines.

With the development and production of future drive units with six, four and three cylinders, the BMW Group continues to bank on its independence as well as on the use of innovative technologies in the largest possible number of vehicle concepts. The new BMW Group Efficient Dynamics family of engines uses a standardised set of design principles and a significantly increased number of common components for both petrol and diesel engines. The new BMW modular engine system is based upon the in-line engine principle as well as on the BMW TwinPower Turbo technology package. The high degree of commonality within the BMW modular engine system strengthens sustainability in terms of both economy and ecology.

The new BMW modular engine system allows three, four and six-cylinder power units to be developed, with various power outputs. This scalability lays the groundwork for a broad performance spectrum and thus for diverse, worldwide application in vehicle concepts within the BMW Group. Independent of the number of cylinders, the type of engine and power output, each power unit meets the excellent standards which define engine development in the BMW Group in terms of efficiency, power delivery and running smoothness.

These petrol and diesel engines of the future with three, four and six cylinders will be manufactured with a maximum degree of flexibility at the BMW facilities in Munich and Steyr. By 2012, the BMW Group will have invested almost 300 million Euros in at both production locations.

The latest innovations deliver the highest efficiency: four-cylinder petrol engines and six-cylinder diesel engines with BMW TwinPower Turbo technology and anticipatory transmission control system.

BMW has further increased its lead in the reduction of fuel consumption and emissions, underlining its pioneering role by deploying BMW TwinPower Turbo Technology in additional engines in the current range of models. At the Innovation Day 2011, the BMW Group will present the new 2.0-litre fourcylinder petrol engine in addition to the new version of the 3.0-litre six-cylinder in-line diesel unit, equipped with this technology package. In the new BMW X1 xDrive28i, this engine has improved the acceleration of the vehicle from zero to 100 km/h, taking just 6.1 seconds and has reduced the average fuel consumption in the EU test cycle to 7.9 litres per 100 kilometres - an improvement of 1.5 litres or 16% compared with the previous model. The new, sportier and yet more efficient diesel enables the BMW 530d xDrive to accelerate from zero to 100 km/h in 6.1 seconds at an average fuel consumption in the EU test cycle of 5.7 litres per 100 kilometres.

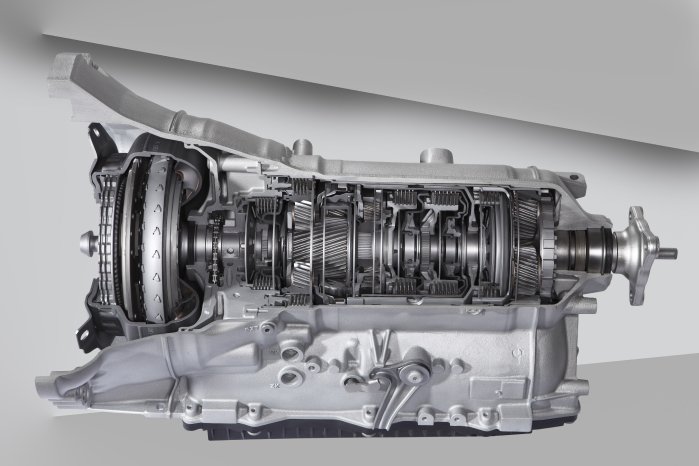

An anticipatory transmission control system for the eight-speed automatic transmission is a further innovation which will be presented by the BMW Group. This system, which is currently in the advance development stage, allows the shift characteristics to adapt to the current driving situation by networking with other vehicle components and incorporating data from the navigation system. In this way, efficiency and driving comfort as well as dynamics are increased appropriate to the situation.

Hybrid technology and electric mobility: the BMW Group banks on in-house development.

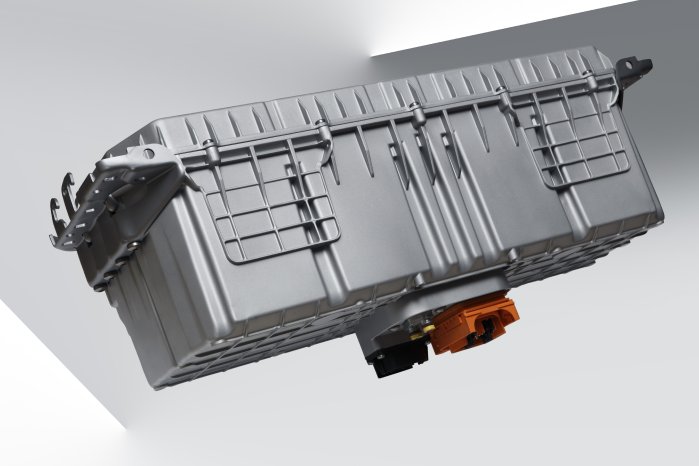

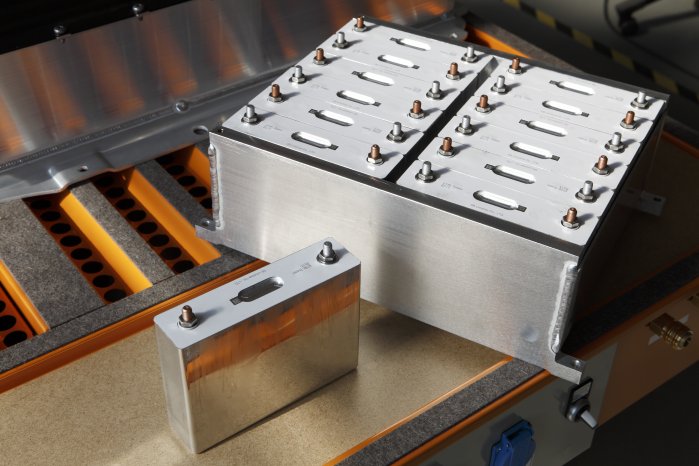

The BMW Group is single-mindedly forcing electrification forward, with the further development of hybrid technology and electric drive systems. The goals anchored in the company's strategy for sustainability are being most effectively pursued with the deployment of BMW ActiveHybrid Technology and electric mobility. The electrification of the drivetrain has created optimised opportunities for mobility independent of fossil fuels, as well as for wideranging reductions in CO2 emissions thanks to the use of renewable energy. The BMW Group strongly believes in its own in-house development and production expertise for the key components: high-voltage storage system, electric motor and power electronics. The company's technological capabilities in drive systems, unmatched anywhere in the world, are thus being expanded to include the field of electric mobility.

A rigorously applied modular approach ensures that the appropriate components are precisely adjusted to meet the requirements of the respective model. The concept of in-house development and an increase in the vertical range of manufacture allow the BMW Group to apply its technological expertise to great effect in optimising the power yield, range and service life of the battery, the power density and efficiency of the electric motor, as well as model-specific control functionality of the power electronics. Furthermore, the high level of quality of all of the systems is guaranteed by the very close cooperation between component development and production.

Intelligent lightweight construction: targeted innovation-heightening efficiency.

When resolving the conflict of objectives which arises between the multitude of demands made on an automobile in the premium segment on the one hand and the pursuit of maximum efficiency on the other, first and foremost weight optimisation is a central consideration, in addition to the optimisation of the effectiveness of the drive system. The concept of intelligent lightweight construction is the ideal prerequisite for realising the unmistakable character of a BMW or of a MINI at the lowest possible vehicle weight. Intelligent lightweight construction methods are found and consistently applied in all areas of automobile development - in the vehicle body construction, in engine production, in chassis technology and even in the design of the interior.

The latest examples of weight optimisation achieved by the use of innovative materials and production techniques will be presented at the Innovation Day 2011. These include the innovative mix of materials in the bodywork of the new BMW 5 Series as well as a novel concept for a particularly efficient use of materials when using carbon fibre reinforced plastic (CFRP).

Moreover, the engine development engineers are working on innovative components which will not only result in less weight but also in a further decrease in the level of noise emissions for both petrol and diesel engines. In the chassis area, various innovations are in development which will lead to decreased fuel consumption while adding a marked boost to driving pleasure in parallel to weight optimisation. Since any reduction in the weight of unsprung masses and in rotating masses in particular has a direct effect on the agility of the vehicle, the BMW Group places great importance on weight optimisation in the areas of suspension, wheel control and brake systems.