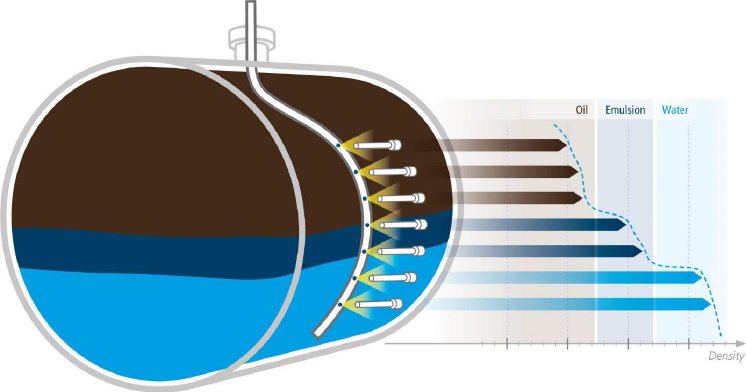

If a clearly defined interface is formed, different technologies can be used for interface measurement. If a larger emulsion layer is formed, for example, when using “opportunity crudes”, with a significant density gradient change from oil to water, the measurement with alternative technologies can lead to errors. These cannot determine the height of the emulsion layer and always assume only one separation layer (or interface). This can lead to misinterpretations and the level is either too high or too low.

If the level is too low, hydrocarbons can be entrained with the water/brine effluent and be sent to the waster water treatment plant, where it can cause environmental issues and potential penalties. If the level is too high, it can cause the electrostatic grids to short, therefore potentially allowing water, salts and minerals to be carried over with the crude oil, where water can damage to the distillation columns, salts can cause corrosion issues and fouling of heat exchangers/furnace tubes and minerals such as iron (Fe) can deactivate downstream catalyst.

EmulsionSENS from Berthold - optimum control of the desalting process

In addition to controlling water and brine levels, the EmulsionSENS interface measuring system from Berthold Technologies allows you to continuously monitor the gradient change in density to ensure that the water content in the area of the electrostatic grids stays within defined limits, preventing short circuits. In addition, the emulsion layer can be kept continuously at the desired level with the help of an EmulsionSENS, which leads to a significant reduction of the “emulsion breaker chemicals”.

Thus, we reduce the probability of upsets for our customers and maximize throughput in the desalter. This process optimization saves money in the long term. According to customers and experts, these are savings of $100,000 to $300,000.

We offer you tailored measurement solutions that meet the requirements of the refinery with the highest degree of accuracy and stability.

For more information please our website: https://www.berthold.com/en/pc/news/interface-measurement-oil-emulsions-water-desalters