Textile machines need it, but, for example, so too do small injection molding machines or applications with closed hydraulic circuits – highly-dynamic movement with simultaneously highly effective torque. In these applications, servomotors are very stressed and have to be cooled well as a result. The right temperature is provided by water cooling, which allows a relatively small motor to be used for a high nominal power. For mechanical engineers, this means better mechanical properties, lower costs and better economic efficiency.

Water cooling saves space and allows for an almost seamless motor range

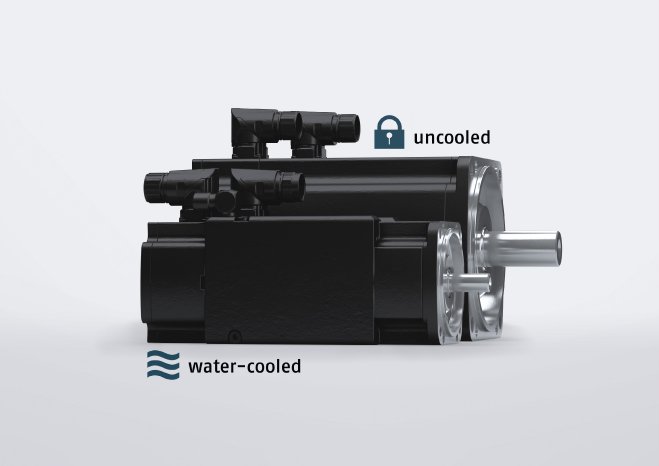

In addition to saving costs, the small water-cooled installation sizes also have other advantages in relation to the installation space. Uncooled or surface-cooled is usually insufficient for highly dynamic applications and air-cooled motors require extra installation space for the fan. With water-cooled motors, the housing is identical in design to an uncooled version and thus combines the advantage of maximal cooling with minimum dimensions. Another positive aspect of heat dissipation using the cooling medium of water is that the motors can be placed next to each other, even in close installation, without heating each other up. Ideal, for example, for textile machines, plastic machines as well as forming and bending machines.

Baumüller completes its series with the water cooling of servomotors in sizes 45 and 56, making them the only manufacturer to offer servomotors in smaller sizes with all cooling methods.

https://www.baumueller.com/...

https://www.youtube.com/...

https://www.xing.com/...üllergruppe

https://www.linkedin.com/...