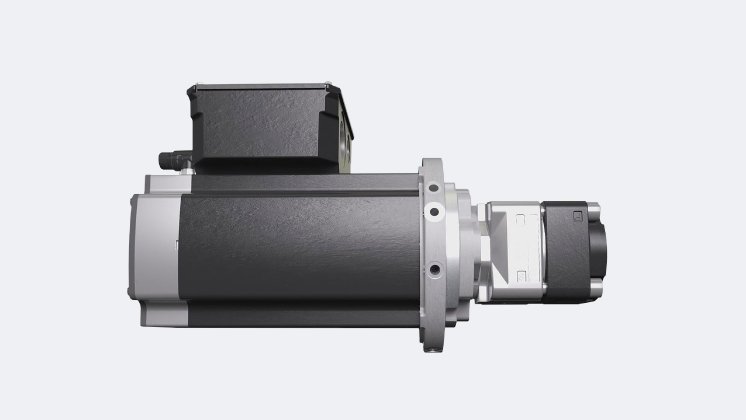

Baumüller offers its motors for three different motor-pump combinations:

· Standard Line - attachment of the pump to the motor via coupling, pump support and base flange

· Advanced Line - direct attachment of the pump onto the motor via internal toothing in the motor shaft

· Performance Line - direct attachment of the pump via the internal toothing combined with circulating oil lubrication

New size

The DS2 and DSD2 motors have now also been developed in size 132 with the option of internal toothing, especially for the Advanced Line and the Performance Line, to implement direct attachment on the respective pump. This dispenses with the coupling and pump support as is the case with classic servo pump versions, which has the advantage of a shorter installation length and therefore a smaller machine installation area. Furthermore, direct attachment eliminates the need for mechanical parts. In this way, the machine manufacturer benefits from lower storage costs.

Baumüller thus completes its motor portfolio for servo pumps and now offers machine manufacturers full flexibility depending on the application case.

www.baumueller.com/...

https://www.youtube.com/...

https://www.xing.com/...

https://www.linkedin.com/...