New location in the InPark A81

The last 50 years have seen DREHER Automation develop, design and produce individual automation systems for forming and forging presses. The innovative mechanical engineering company, based in Sulz am Neckar, supplies automotive and white goods manufacturers all over the world.

However, over time, the business success of DREHER Automation has resulted in the Renfrizhausen location clearly becoming too small. After a long search, management found what they were looking for in the Sulz am Neckar and Vöhringen intercommunal industrial estate: The move to InPark A81 is scheduled for the end of 2019. The groundbreaking ceremony for the new building took place on 19 September 2018.

With the new location, DREHER Automation is investing in a continued successful future just in time for its 50th anniversary. The new building not only enables a significant increase in productivity, but also optimal mapping of process sequences and an attractive design of workplaces.

Innovative technology at EuroBlech

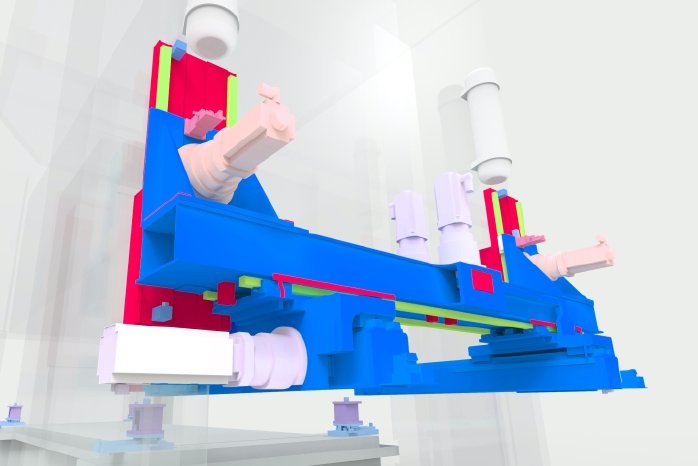

Further important factors for future success are the innovations from DREHER Automation. This also includes the FlexMotion technology. Thanks to its flexible design, the universal transfer automation for sheet metal forming can be used in all common press types and makes. As the heart of the forming press, it guarantees high dynamics, smooth running, flexibility, process reliability, productivity as well as availability and offers state-of-the-art control technology.

At EuroBlech 2018, DREHER Automation is presenting a new expansion stage of the proven technology. By reducing the mass in the closing path, this guarantees an even higher output, especially with smaller, highly dynamic presses. Interested parties can find out more at Stand H82 in Hall 27.

A wide product range for every need

However, the transfer automation is only one component since the heart of the forming press will only function optimally if the entire system concept is coherent. This is where the wide product range of DREHER Automation comes into its own. Thanks to its large product range, the company can automate every forming press according to the customer’s needs.

Find out more at www.dreher.de