Core shooing simulation is primarily comprised of two distinct steps: the core-box filling process and the gassing stage (i.e. the through-flow of a core box cavity). No other software beyond Arena-flow® can more accurately simulate these specific steps. Its accuracy is derived from CPFD and allows for far-reaching potential in terms of simulation accuracy.

Comparable software applications use simplified methods for modeling the behavior of sand. Specifically, they portray sand as a fluid, rather than a particle. Here, Arena-flow® shows its strength, as it provides a realistic representation of the actual interaction between sand grains and the air-flow within the tooling. The resulting difference between the systems has serious implications for foundries seeking a more stable and robust process. Arena-flow® provides the necessary assurance to guarantee – via simulation – an advanced stable process, in terms of quality cores for production.

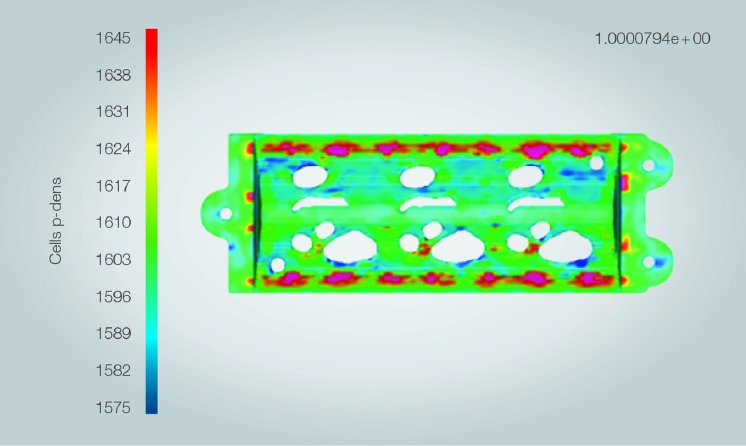

An additional benefit of Arena-Flow® software is its ability to provide compaction models (Fig. 1). In this example, one can visualize whether or not the core is completely filled and the compaction is uniform. Other valuable simulation models are also available through Arena-flow®: mold material distribution, geometrical pressure, flow conditions (i.e. of the geometries), tool wear, gassing and the overall observation of the filling dynamics in definable sequential steps. Finally, Arena-flow® also provides a unique feature in the use of exact core fractions – both with mono sand systems and mixtures involving special sands/additives.

“When it comes to optimizing core making, ASK Chemicals has principally used Arena-flow® to great success,” Christof Nowaczyk, Productmanager Design Services Europe & Asia, says. “We have been involved in developing the software from the beginning and are delighted that the new generation allows us to offer this tool on license to Windows users.”

The Windows version of the software can be experienced in use at the foundry supplier’s exhibition booth at GIFA in Hall 12, A22. Here, live simulations using the Arena-flow® simulation software for core shooting are presented regularly.