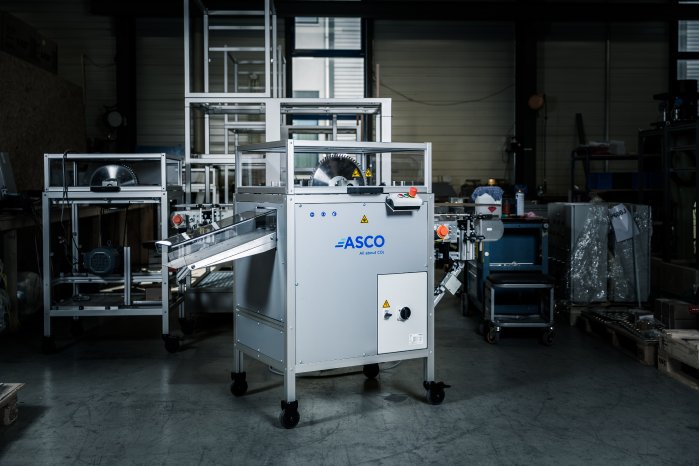

The Swiss dry ice specialist offers absolute system reliability. Thus, the ASCO Active Dry Ice Saw - AAS can be integrated into different production centers. For example in combination with the ASCO dry ice machines BP420i, BP425i, the ASCO Reformer A700Ri as well as with the ASCO Wrapping Machine APM120 and APM140.

Marco Pellegrino, Managing Director, ASCO CARBON DIOXIDE LTD, emphasizes: "With the world's first series-produced active dry ice saw, ASCO underlines its ambition to be one of the market leaders in dry ice production. With our product portfolio, we are able to cover the wishes of our customers and to constantly optimizing the portfolio. We’ve also achieved this with the new type of dry ice active saw," says Pellegrino.