Formula category racing cars are the pinnacle class in motor sport. No other series of motor racing vehicle represents a comparable requirements profile of technical expertise and driving skills - not to mention the financial capacity of those involved. Thus, the experience and new ideas gained from formula racing always have an influence on the development of series vehicles. Proof of the efficiency of materials such as aluminium and carbon fibre was first obtained from their use in racing cars. Cost-reducing design technologies, such as Rapid

Prototyping, can also trace their roots to motor racing before gaining recognition in other areas of industry. Developing a formula vehicle provides crucial experience for the automotive engineers of the future - of inestimable value in their professional careers.

Quick and economical

The “Formula Student” program, set up in 1981 by the Society of Automotive Engineers (SAE), provides engineering students with an extraordinary opportunity to get to grips with the demands of engineering practice at an early stage of their careers. Ultimately, it is not simply a matter of building the fastest car, but of finding an intelligent compromise between engineering design and race performance, financial planning and sales claims. The “Formula Student” (FS) concept is proving very popular and is meeting the expectations of students at the Wolfsburg University of Technology. Since it was set up in 2003, the project - operating under the name of “Wob Racing Team” - has designed and manufactured a competition racing car in the Formula SAE class.

The Monoposto vehicle must not cost too much, and must be reliable and easy to drive”, said Steffen Niemann, project technical manager of “Wob Racing”, describing the challenge that faces his team. Following initial successes at the FSG competitions in the United Kingdom and in Germany, the students are now building the racing generation for 2006 and finding ways to achieve pole position. In Arnold Umformtechnik GmbH of Forchtenberg in SW Germany, they have found a development partner who is supporting the project not merely financially, but in particular by the transfer of its technical expertise.

Fastening technology under extreme loads

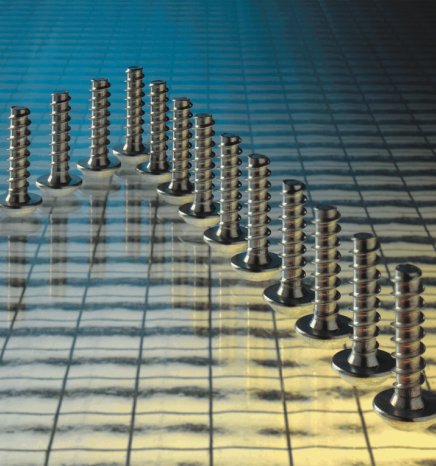

Arnold was able to contribute its specialist knowledge as students continue to perfect the fastener technology used in the vehicle. “The use of thread-forming Remform screws is helping our work in every discipline required,” argued project manager Niemann. “By using Remform, we have shortened the process chain, reduced the costs of assembly, of processing and the parts, and are creating an additional safety cushion” said Niemann, summing up the first year of collaboration.

“The Remform screw we are using here is the logical enhancement of the idea that these fasteners should take on additional functions when screwed in,” continued Professor Paul Wollschläger, deputy director of the Vehicle Construction Institute. The principle of direct screwing is that, as it is screwed in, the screw takes over some of the steps of the manufacturing process that, in conventional manufacturing, would need to be carried out as separate work procedures. As the screw is screwed in, a gimlet incorporated into the tip first forms the appropriate through-hole diameter, after which the screw taps into the bore thread with its own thread. “There is no need to drill the hole and cut the thread, so less assembly time is required. We save on the machines and tools necessary to do that, and on wear, so assembly costs go down,” continued the manufacturing specialist. However for it to be deployed without problem, the forming material must possess a certain minimum ductility.

A patented safety benefit

This is the case with the use of Remform at Wob Racing. The WR01 model’s intake system is manufactured as a rapid prototyping part from PA-6. It is not just the injection strip that is screwed to it, but the temperature sensor has to be fastened to it as well. Remform screws have proved to be the problem solver in this area. The patented thread geometry provides the fastening with a considerably higher strip load and offers a greater difference between screw-in torque and overturn torque than the traditional 30o low angle screws. The screws, which are therefore consistently tight, provide additional safety room - particularly necessary under the extreme conditions of motor racing.

At the same time the much slimmer budget achievable with Remform proves to be a real competitive advantage. “Even in this coming year, I calculate that we will be able to continue to maintain our lead over the competition, because our Formula Student competitors are still underestimating the issue of fasteners,” forecast Niemann. “But once they do the cards will be reshuffled and a new game will start”. Because competition never sleeps – it sometimes just has one eye shut.