Arnold NextG is at the forefront of agricultural innovation, demonstrating its state-of-the-art system with the Fendt 942 Vario. This tractor, a powerhouse of 409 horsepower with all-wheel drive, is a glimpse into the future of farming. Equipped for teleoperation, semi-autonomous or fully automated functions, it showcases versatility in agricultural applications.

The Fendt 942 Vario, weighing nearly 12 tons, is enhanced with Arnold NextG's multi-redundant driving and steering system. This advanced system allows control beyond the traditional steering wheel or joystick; it includes remote control options for direct line-of-sight operation or desk-based teleoperation. Its sophisticated design incorporates multiple redundancies and a fail-operational safety concept, ensuring reliability even when external systems, like AD-Stacks, encounter errors.

Car-like Steering Feel in a Tractor

Arnold NextG introduces a revolutionary concept to tractors: a car-like steering feel. By digitizing key vehicle functions such as steering, throttle, and brake, they have reimagined the tractor's steering wheel. The patented Virtual-Shaft Technology synchronizes the steering wheel position with the wheel steering angle, effectively creating a virtual steering column. This technology ensures the front axle's alignment with the steering wheel, mirroring the functionality found in trucks and cars, including the steering wheel's automatic return to the 12 o'clock position.

The addition of Arnold NextG's Force-Feedback Technology further transforms the driving experience. This technology provides the driver with real-time feedback about varying road and terrain conditions, axle load, and the lateral force from attached implements. This adaptive steering response not only enhances operational safety but also significantly elevates driver comfort.

Adaptive Steering as a Safety Feature

The integration of speed-dependent steering force allocation and variable steering ratios in Arnold NextG’s system simplifies and enhances the driving experience. These features, coupled with the multi-redundant steering system, make driving both more intuitive and comfortable.

Joystick with Road Approval

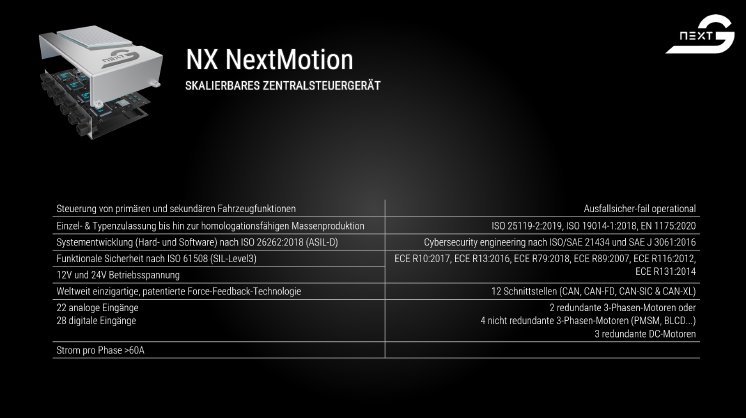

Arnold NextG's NX NextMotion, adhering to all relevant safety standards, paves the way for a new era in tractor operation. With its compliance, the traditional steering column becomes redundant, allowing for joystick-only operation, even on public roads. This opens up exciting possibilities for reimagining the tractor’s cabin design, from a swiveling driver's seat to a customizable control unit that combines seating and controls.

Maneuvering, positioning, and coupling via remote control

NX NextMotion integration revolutionizes the remote control of attachments, enabling precise maneuvering, positioning, and coupling. This system not only allows for millimeter-accurate control but also incorporates an advanced braking system that is speed-sensitive and actively engaged, ensuring consistent operational safety.

Digital Transformation of Driver Tasks

Kevin Arnold (CEO Arnold NextG) highlights the transformative potential of our electronic steering and braking system: “Equipped with interfaces essential for autonomous driving systems, our technology paves the way for transferring human driver responsibilities to digital platforms. This innovation supports various operational modes, ranging from fully automated to semi-autonomous, teleoperated, or remote-controlled vehicles.”

Upgrading Existing Fleets with Fail-Operational Solutions

In the dynamic sectors of agriculture, construction, and forestry, automating machinery is key, driven by cost and efficiency. Introducing vehicles that minimize the need for human operation reduces risks like downtime and optimizes operational costs. Arnold NextG's drive-by-wire technology aims to not only automate new agricultural machinery but also upgrade existing fleets. This technology supports a range of operations from joystick control to full autonomy, adhering to all safety standards and, where applicable, road regulations.

Centralized Automation Interface

NX NextMotion seamlessly integrates into the vehicle system, controlling primary functions (steering, throttle, brake) and secondary features (gear selection, signals, horn, wipers) via diverse interfaces including touch displays and voice control, or directly through autonomous driving systems. This integration networks all vehicle systems in real-time, creating a central hub for automating technical processes and enhancing operational safety.

Arnold NextG's advanced steering and braking system continuously gathers and analyzes road-to-wheel friction data. This vital information is shared with autonomous driving system providers and sensor manufacturers (camera, radar, LiDAR), ensuring that vehicles can always return to a safe state, even in case of autonomous system errors.

Accelerating Development and Efficiency

NX NextMotion’s system architecture enables the consolidation of various safety-critical functions previously scattered across multiple control units. This integration fosters rapid development and heightened efficiency in vehicle manufacturing, as Kevin Arnold emphasizes.