In this first part of our blog series, we take a systemic look at the topic:

- What does "autonomous" mean in technical and regulatory terms?

- Which system layers enable automated mobility?

- And what role does drive-by-wire play in the background?

Autonomous mobility is not the result of a single vehicle, but of a distributed system that processes real-time data, makes decisions, and triggers physical movements – safely, transparently, and under all operating conditions. SAE International defines six levels of automation from Level 0 to Level 5 – an international reference framework that has become the standard for developers, regulatory authorities, and industry.

The majority of marketable systems currently operate between Levels 2 and 3. Level 4 is technically possible – but only in clearly defined zones, with defined environmental parameters and a comprehensive redundancy structure. According to the Federal Ministry of Digital and Transport (BMDV), the widespread use of autonomous systems will only be possible with the appropriate infrastructure and comprehensive standards.

The functional layers of autonomous mobility

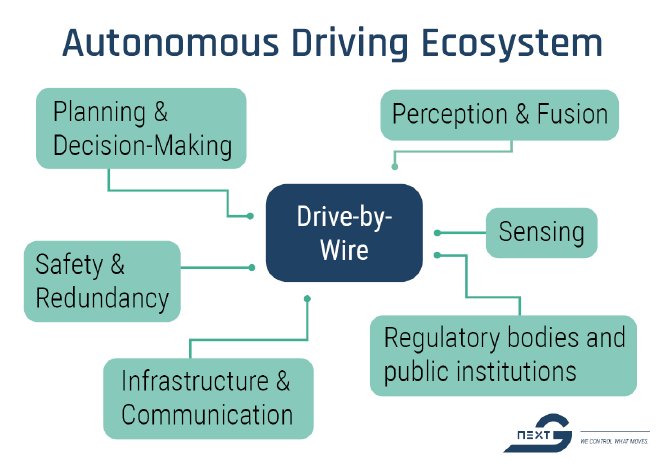

Technically, autonomous mobility is based on six layers that are closely interlinked:

- Sensors: LiDAR, radar, camera, ultrasound – provide raw data on the environment

- Perception & fusion: real-time interpretation and combined environment models

- Planning & decision-making: Trajectory calculation, maneuver logic, prediction

- Actuators: Fully electronic execution via drive, steer, and brake-by-wire

- Safety & redundancy: Standards compliance (ASIL D, ISO 21434), fault tolerance, fail-operational

- Networked infrastructure: V2X, HD maps, 5G, cloud backend, teleoperation

No company can implement autonomy alone

Reality shows that successful autonomous systems are not created in silos, but in ecosystems. OEMs, suppliers, software companies, sensor manufacturers, infrastructure providers, and regulatory authorities are increasingly working in strategic alliances.

One example is Volvo Autonomous Solutions, Volvo Autonomous Solutions provides an example of this by integrating Aurora software into its own vehicles and safety architectures. Redundancy, cybersecurity and safety-by-design are central here – an approach that is setting the tone for the entire industry.

Arnold NextG is also part of such ecosystems – with solutions ranging from autonomous shuttles in public transport to remote-controlled machines in mining, agriculture, and logistics.

The role of drive-by-wire in the ecosystem

Drive-by-wire is considered a basic requirement for Level 4 and Level 5 applications. This is because only fully electronic control of the drive, steering, and brakes allows complete decoupling from humans – whether for autonomous driving or remote control.

- ISO 26262 (ASIL D) describes functional safety in road vehicles and specifies processes for risk minimization through systematic error detection.

- IEC 61508 (SIL3) is the overarching international standard for electrical/electronic safety systems and forms the basis for ISO 26262

ISO/SAE 21434 defines cybersecurity requirements throughout the entire vehicle life cycle. - UNECE R155 requires a cybersecurity management system for connected vehicles, which can be covered by ISO/SAE 21434, for example.

Beyond Automotive: Autonomous systems in special applications

Autonomy is no longer limited to traditional passenger cars—demand extends far beyond the core automotive business. NX NextMotion is already in use in numerous sectors:

- Public transport: Level 4 shuttles enable mobility in rural areas

- Logistics & ports: teleoperation in 24/7 operation

- Agriculture: RTK-controlled field robots with force feedback

- Mining: vehicles for hazardous, inaccessible areas

- Defense: semi-autonomous convoys with NATO compatibility

- Inclusion: intuitive mobility for people with disabilities

Conclusion: System thinking determines progress

Autonomous driving is not a vision – it is reality in modular, cooperative systems. Anyone who wants to survive in this environment needs reliable partners, certified systems, and a deep understanding of technological interdependencies. With NX NextMotion, Arnold NextG delivers a platform that meets these requirements – robust, scalable, and ready for real-world use.

In the next parts of this series, we will focus on the individual levels – starting with sensor technology and the question: How do machines actually see their environment?

We control what moves.