The all-rounder suction plate with its extremely slim, soft and flexible seals enables the handling of workpieces even with minimal suction surfaces and a wide variety of structures. According to the motto "Simply lift everything!", the innovative CLAD-BOY® system from AERO-LIFT thus guarantees highly efficient and ergonomic work on the construction site. There is no longer any need to change over and exchange sponge rubber seals, for example, between working with different workpieces. In addition, maximum service life is guaranteed by the high-performance and extremely resistant material of the seals. The full elastomer is UV-, ozone- and extremely resistant even at high plus and minus temperatures.

The total load capacity of the CLAD-BOY® with the new all-rounder suction plate is 300 kg. The new type of suction plate is the first on the market to universally cover all task areas and is thus a true innovation in the field of mains-independent vacuum lifting devices.

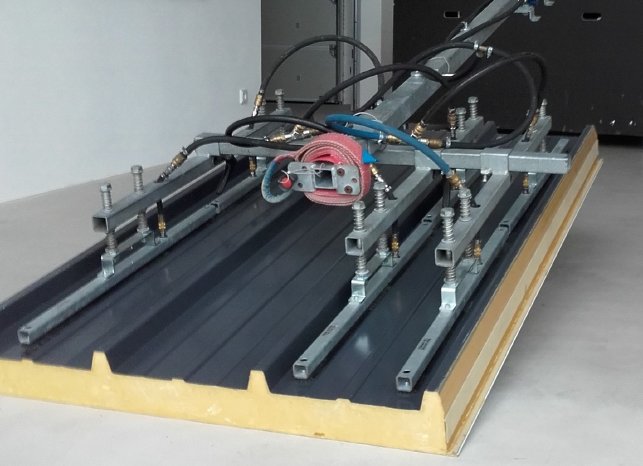

In addition to this universal solution, AERO-LIFT was able to present its further developed STORE-BOY XL at the trade fair, which is both a flexible and convenient storage and transport unit for the CLAD-BOY®. The resulting compact assembly of the unit including the required accessories (traverses, suction plates, extensions) fits on the loading area of any small van and thus saves transport costs in the long term. The integrated parking position of the new STORE-BOY XL allows the CLAD-BOY® to be assembled without a crane on the ground, and at the end of the working day it can be stored until its next use. Thanks to the STORE-BOY XL, the CLAD-BOY® can be assembled by just one person for use on roofs and walls. The transport and storage unit can be easily moved by forklift, crane or lift truck. An integrated box for tethers and other accessories completes the new STORE-BOY XL. Users of the previous STORE-BOY unit can also rejoice: with a minor adjustment, this is fully compatible with the new STORE-BOY XL. On request, AERO-LIFT can supply a retrofit kit for the previous system so that all optimizations can be used here as well.

More information about the CLAD-BOY®, the new all-rounder suction plate and the STORE-BOY XL from AERO-LIFT is available online at: https://www.aero-lift.de/...