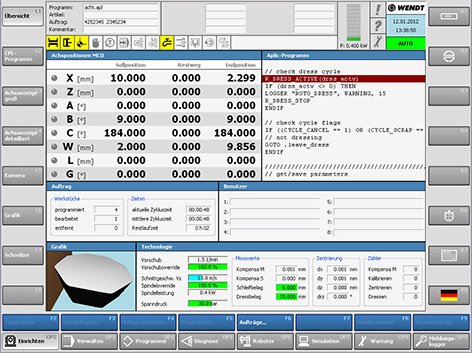

Due to the improved structuring of the software, the operator of the machine can now move from one template for geometry data or process functions to the next without having to close the previous one. This makes it easy to quickly check all of the grinding data with just a few clicks.

In addition, a rapid-programming dialog mode is also available for the machine. This is especially interesting for users who do not want to have to deal with the programming language. The user can define the entire geometry and all information that depends on it by simply entering appropriate data into the dialogs shown on the screen. The programmed workpieces can then be displayed three-dimensionally in order to check the programming before actually grinding the first piece.

For Complex Workpiece Geometries

The WAC 715 CENTRO peripheral grinding machine is the answer to meet the requirements that are becoming ever more complex in the fully automated production of inserts. For very complex workpiece geometries, it offers with its five CNC axes many different possibilities, such as, for example, machining periphery shape, protective chamfer and chip breakers all in a single clamping. A special feature of the machine is that two workpiece axes can be rotated by a full 360°.

Applications with Two Grinding Wheels

The demand for DUOWHEEL applications with two grinding wheels is continually growing. These offer, for example, new possibilities in workpiece geometry and allow the number of different clampings to be reduced. DUOWHEEL combines the benefits of the proven face wheel with those of a peripheral wheel, which can have a different grain size and binder. At the AMB trade fair in Stuttgart, Wendt GmbH will be demonstrating at the 3M booth in Hall 08, Booth C52, the machining of a plunge-cut geometry on a face wheel by utilizing both 360° workpiece axes.

About WENDT

WENDT GmbH of Meerbusch near Düsseldorf became a 100% subsidiary of 3M at the end of 2011, and is a world leading supplier of precision grinding machines for ultra hard materials such as PCD and CBN, and also for Cermet, ceramics and hard metals. WENDT is also the only supplier in this field who is able to provide the machines, tools, service and application technology from a single source.