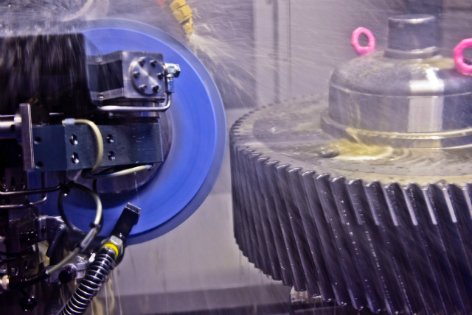

The predominant feature of the new Cubitron II ceramic grains developed by 3M for this abrasive is their precisely-shaped, uniform-sized which results in even greater efficiency than ever before for all grinding processes. As the triangular shaped grains with their aggressive cutting edges and fractal properties wear, they continuously fracture to form new sharp points and edges, thus making the abrasive self-sharpening.

These grains therefore provide not only a faster cutting process, but also a much cooler process compared to conventional ceramic abrasives. In addition, thanks to these properties, abrasive materials made with the new grains last much longer and also produce much cleaner surface finishes.

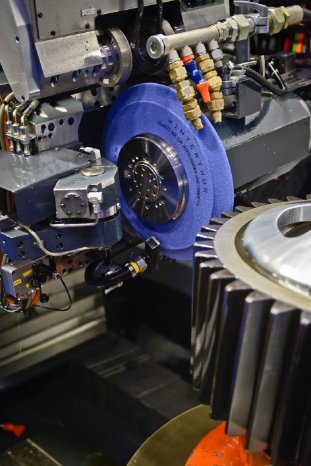

Winterthur Technology focused its long-standing expertise in manufacturing bonded abrasives to combine the precision-shaped grains with state-of-the-art bonding systems and pore-inducing agents to produce truly revolutionary grinding wheels. Due to their high and uniform material removal rates, these wheels can reduce machining times by up to 50%. This significant reduction has already been demonstrated in the first uses of the innovative wheels to machine large diameter gears of hardened steel, such as those used in wind turbines, shipbuilding and steel works.

Depending on application, the new wheels have shown a two- to seven-fold increase in service life, which, in turn, results in dramatic savings of previously required set-up times. Taken all together, the improvements provided by the innovative abrasives translate to much higher productivity and lower costs per part.

The new 3M Cubitron II Grinding Wheels made by Winterthur Technology for single rib gear grinding are available ex-stock in two different grain concentrations and in the standard dimensions for this application.

About Winterthur Technology Group

The Winterthur Technology Group, a 100% subsidiary of 3M, is one of the world’s leading manufacturers of innovative grinding solutions. The group holds a unique position in the market in that it is the only manufacturer that offers the full range of grinding tools and machines from a single source. Its bonded abrasives are used particularly in the automotive, aerospace, tool machine, toolmaking, glass and steel industries especially for the precision grinding of ultra-hard materials.