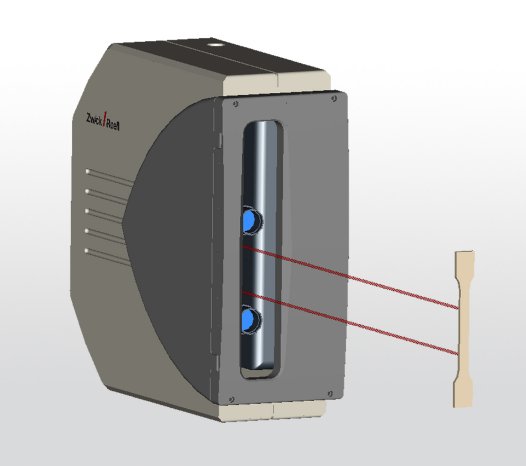

The Zwick Roell Group, building on its global success as a pioneer of non contact extensometers, has developed a new product which is set to revolutionize the measurement of strain. Designed for both the measurement of Young’s Modulus and strain at specimen failure using only one device, the laserXtens makes no contact with the specimen under test and requires no specimen marking.

For research and development applications, the laserXtens brings major benefits due to its high resolution, accuracy and flexibility, whilst for production control especially using robot technology, the lack of specimen marking and operator involvement enables cost effective, safe, and easy to use operation.

The laserXtens meets class 1 of ISO 9513 (Class B2 of ASTM E83), and is designed to test materials in applications where a contact extensometer might be unsuitable due to its physical contact with the specimen or the whiplash experienced at specimen failure. It also enables the testing of complex component shapes which would preclude the attachment of a traditional contact extensometer.

Due to their mechanical construction traditional clip-on extensometers have limited capability when testing small components. The laserXtens can measure strain with a gage length as low as 1.5mm and at temperatures up to 1600 deg.C.

An optional transverse measuring system enables the measurement of r values and Poisson Ratio.

The features of the laserXtens are totally integrated into Zwick’s testXpert® software and make the total testing system very powerful and easy to use.

Zwick believes that the laserXtens extensometer will bring major benefits to the metal, composite, plastics, and rubber industry, and component testing in the Aerospace, Automotive, Medical, and the Building Industry.