- Simplification of the handling and loading of specimen into the fixture significantly reduces the testing time.

- Handling and alignment errors and invalid tests are virtually eliminated resulting in unrivalled precision and reproducibility of test results.

- Flexibility in design allows specimens with different geometries to be tested.

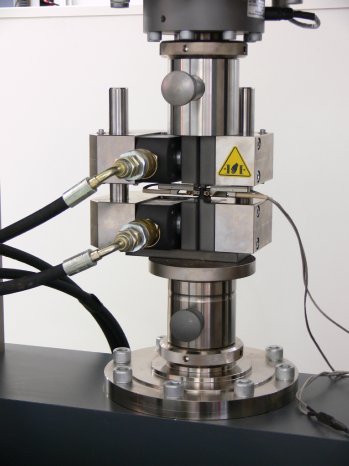

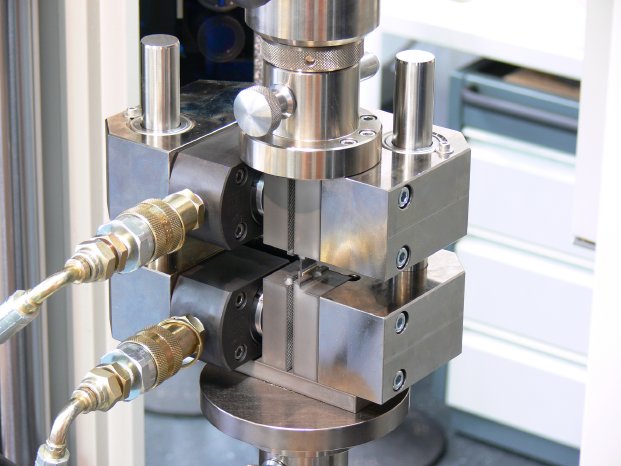

The new Hydraulic Composite Compression Fixture (HCCF) now available from Zwick was developed and patented by the IMA Material Research and Application Technology in Dresden and is used specifically for the testing of carbon-fibre-reinforced plastics (CFRP) and glass-fibre-reinforced plastics (GFRP) with unidirectional fibre-reinforcement. It was primarily designed for determining compressive characteristics and is suited for testing standards such as prEN 2850, DIN EN ISO 14126, DIN 65380, and QVA-Z10-46-38.

The open C-frame construction facilitates the simple and fast exchange of specimens, and in addition the attachment of extension measurement systems can be easily carried out. Due to the design and construction, the specimen is very precisely aligned as tolerances due to the set-up in traditional jigs, especially with a wedge clamping principle, have been avoided. A specimen guidance system minimizes any measurement error and variance, and in addition the test results are largely unaffected by frictional forces, due to the use of friction free ball guides, in the fixture.

The hydraulic clamping force mechanism guaranties a reliable and reproducible clamping of the specimens and the clamping force is applied uniformly and securely across the specimen. As a result the specimens are not subject to misalignment, eccentric forces, or slippage.

Exchange of specimens, inspection and cleaning of the clamping surfaces is simple to perform as the moveable jaws are magnetically attached to the fixture.

With the appropriate material selection the compression testing device can also be used at high or low temperatures in a range from -60 to +95° C. The ability to utilise either mechanical or high resolution optical strain measurement systems means that, in most cases, additional time can be saved by avoiding the need to prepare the specimens with strain gauges.