At the core of Zwick’s roboTest® robotic testing systems is the advanced testXpert® autoEdition software. This controls, regulates and monitors processes within the system. It also manages all data, such as parameters, device data and test results. On top of this, the software takes care of process visualisation - displaying status information and device conditions. State-of-the-art web technologies allow continuous process monitoring and remote diagnosis.

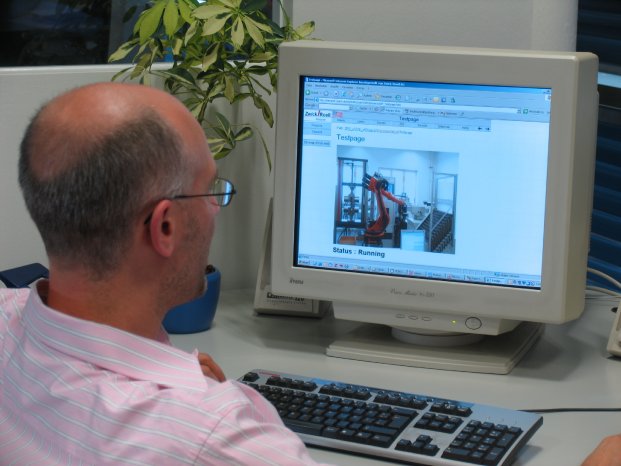

The Webservices software option can send results, together with status and error reports, to any chosen recipient. Text messages can be sent automatically via an SMS gateway and e-mails via an SMPT server. Incorporating live images of the machine from a webcam into an HTML, Internet or Intranet page allows the system and tests to be witnessed in real time from any PC. The operator has access to continuous real-time status updates even when away from the machine and can react quickly to system messages – for example, loading the machine with new specimens.

Remote maintenance can be carried out anywhere via a secure VPN link such as Juniper. All that is needed is Internet access plus an open port in the company’s firewall. Diagnosis options in remote operation allow problems to be corrected quickly and one very useful function is the ability to request status updates directly.

Integrated language-swapping in autoEdition2 allows operators and service engineers to operate the system in their own language. Six languages are installed (English, German, French, Chinese, Spanish and Japanese). Translation into other local languages can also be performed by the customer.

Compared to standard office computers, industrial computers provide much higher levels of ruggedness and reliability as well as much longer product life-cycles. In an emergency the computer hardware can quickly be exchanged and a stored image of the hard drive re-installed, minimizing system downtime.

The software’s modular structure allows it to be expanded at any time and adapted to new testing requirements. It consists of several individual components, including the specimen database, process control, device drivers and optional extra components.

Zwick’s robotic testing systems are so flexible and powerful that they can be integrated with industrial robots and integrated directly into production lines.