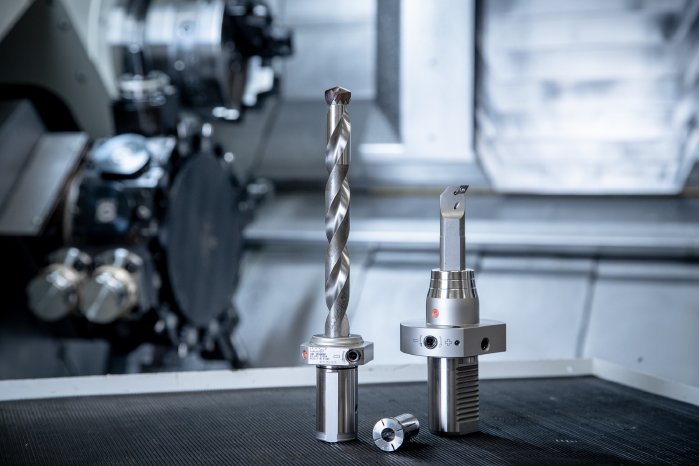

For example, the new version of the CERATIZIT hydraulic chuck is now available with VDI and cylindrical shank connection meaning it can be used in turning and milling centre applications. This latest addition to CERATIZIT’s portfolio is the ideal solution for precision clamping boring bars with a shank tolerance of h7 or, when high vibration damping and repeatability are required.

Another highlight in the new Up2Date catalogue which can also be used for low-vibration machining are the new vibration-damped boring bars. These reliably reduce vibrations and, together with the flexibility of a brand-new exchangeable head system, guarantee top quality at a low price.

CERATIZIT is also introducing another innovation in the form of a short version of the well-known Fullmax solid carbide reamer. The reamer boasts outstanding cutting performance on a wide range of materials, even toughened steels up to HRC62. The short version of the universal Fullmax is even more stable in its application, enabling higher cutting speeds. It also impresses with its long service life and is more attractively priced for short hole depths than the long version.

For workpiece clamping, CERATIZIT presents a new, efficient, and high-precision clamping system for machining centres: The WNT X5G-Z five-axis clamping system. Its key feature is the optimised accessibility from all sides, which enables five- and even six-axis machining. The five-axis clamp is also extremely easy to use and significantly reduces set-up time.

The innovations within the new Up2Date catalogue ensures machining companies continue to equipped to improve their processes by achieving more economical machining. More details can be found at cuttingtools.ceratizit.com.