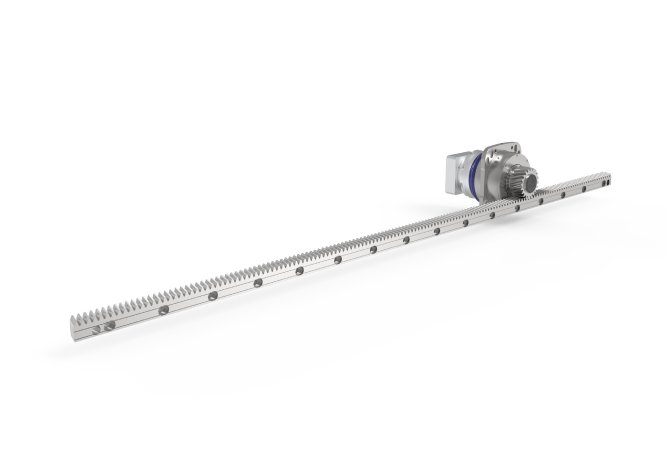

The high-quality 2-meter rack is WITTENSTEIN alpha’s response to increased demand for this length, which enables customers to simplify their assembly processes even further. The y-axes of laser cutting machines, the lifting axes of gantry robots, plasma and waterjet cutters, the telescopic axes of Cartesian robots, tool changers and the 7th axis in robotics are just a few typical applications.

The tried-and-tested 1-meter racks have a reputation for simple transport, standardized stocking and assembly-friendly handling. INIRA® clamping, adjusting and pinning, too, makes assembly even faster and even more efficient. The potential applications for these 1-meter racks include wood, plastic and composite machining centers, metal-cutting machine tools, laser cutting machines and the positioning axes of gantry robots. Case-hardened 1-meter racks are available for very high feed forces.

Linear system solutions from WITTENSTEIN alpha – the right solution for a range of applications

Solutions to suit any application – that’s what WITTENSTEIN alpha linear system solutions are known for. They consist of perfectly matched combinations of a gearbox, pinion and rack. Their possible applications extend from automation to high-precision axes in machine tools. The cymex® sizing software is used for dimensioning depending on the specific smooth running, positioning accuracy, feed force, rigidity and axis configuration requirements. Adapted solutions for re-lubrication round off the systems.