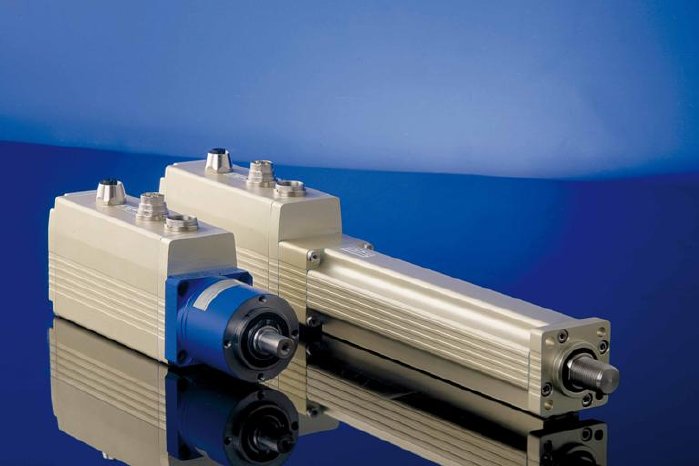

Ternary finds its perfect “playground” in all situations where a pneumatic cylinder isn’t enough and a servo is too expensive and too complicated. WITTENSTEIN motion control’s linear system allows multiple positions to be controlled with utmost precision (over an unlimited number of fieldbuses!) – and at the same time guarantees unbeatable value for money. Compactness, strength, intelligence and precision are the hallmarks of the linear actuator.

Following the realisation of a prototype version, Ternary BLM’s first customers have meanwhile reported its successful installation in real applications. The new all-in-one servo actuator system has evidently kept its promise: in addition to mechanical and electrical compatibility (identical memory and command structure) with the existing Ternary, the “latest addition” convinces with superior maximum force and dynamics. Yet like its bigger siblings, it nevertheless offers substantially more flexibility and controllability than the average pneumatic cylinder ever can. The linear unit can be used to design flexible, top-quality machines integrating vast functionality that are easily adapted to product changes or future expansions. The dynamics of the integrated servo drive enable the achievable clock pulse rates to be more than doubled in practical duty.

The fact that separate switch cabinets and additional wiring or cable ducts can be dispensed with further increases the saving. And since the Ternary actuator system integrates everything in a single device, fewer components are needed so that operating reliability is enhanced. Supported by force control, Ternary not only approaches exactly specified positions – it can also be held or pressed against a body with a predefined force. Ternary positions and stops quickly with a strong holding force and no vibration.

New features, many applications

As with the existing series, Profibus, CanOpen or DeviceNet can be supplied in addition to the serial and parallel interfaces. Over and above the higher drive performance and lower noise level – the outcome of its ingenious operating principle – the servo actuator incorporates several innovative features.

For the first time, a serial interface is standard with all fieldbus variants, making the data setting software considerably easier to use (expensive PC interface cards are no longer required). What’s more, the Ternary BLM system’s internal memory now allows 64 positions to be programmed and controlled instead of the previous 16. Ternary BLM is additionally equipped with a pulse input and A/B encoder output function to permit the actuator to be directly controlled if necessary without a bus interface. A variant with an absolute encoder is currently in the pipeline.

Ternary BLM also brings commercial advantages, using only around 1/3 of the power of compressor solutions with pneumatic cylinders. The WMC linear system requires no maintenance and complies with the IP65 degree of protection.

Ternary represents a particularly effective alternative in the following applications:

• Positioning and format changes in industrial engineering,

• Pick-and-place robots,

• Test bays,

• Valve control in filling systems, and

• CD and chip production (semiconductors):