The WITTENSTEIN booth will also feature Value Line, the new, modular gearhead series, the extended portfolio of servo worm gearheads in the V-Drive series and a new, higher-output simco drive version with an EtherNet/IP interface, an integral web server with Industry 4.0 connectivity and – coming shortly – UL certification. Three altogether impressive exhibits – a handling system that enables automated production of CFRP and GFRP parts with almost 20 brushless DC motors, a heavy-duty multiplier with a custom designed motor and electronics and a tool changer with fully scalable premo servo actuators plus a live demonstration of the web server – will underline WITTENSTEIN SE’s innovative vitality and reaffirm the expertise of the Group's various Business Units.

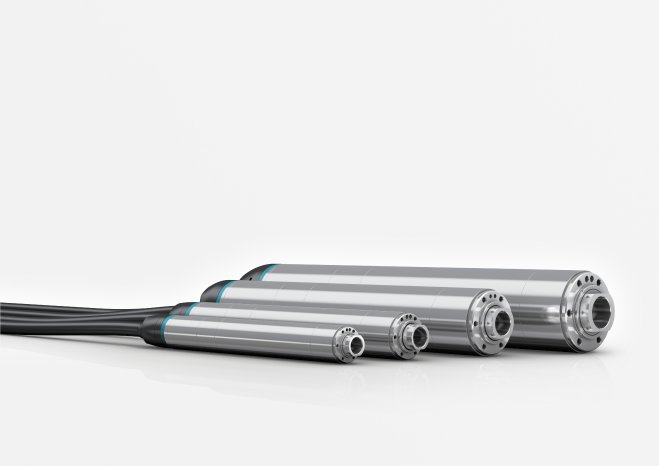

Enormous power, small footprint: industry-standard brushless DC motors with an integral screw

A new series of brushless DC motors with an integral screw was recently launched in the market by WITTENSTEIN cyber motor GmbH for use in highly dynamic positioning axes, especially when the machine has to be installed in a confined area. It is the screw drive, fully integrated in the actuator housing, that makes this series so unique: the servo motor, spindle drive, linear guide rail and encoder system form a self-contained, highly integrated and ready-to-mount unit. The new actuators add even more value when they interact with the simco drive series from WITTENSTEIN motion control GmbH: amongst other things, these limit the end position in the application and home the drives when the machine is started up or restarted. The brushless DC motors with integral screw make a perfect complement to the portfolio of rotary servo motors and actuators in the cyber dynamic line family. They are employed, for instance, in forming and handling technology, the semiconductor industry, packaging machinery and assembly automation. The full stainless steel version with IP65 protection also has many interesting applications in food and beverage plants, such as in highly precise bottling lines.

Individual talents for driving any axis: the alpha Value Line gearhead series

Maximum configuring flexibility, timely availability, lifelong reliability and economic efficiency – these features all help the modular alpha Value Line gearhead series from WITTENSTEIN alpha GmbH set a new benchmark. The performance range for which it was designed is characterized by average precision, dynamics and power density requirements. Several product types – for example HIGH TORQUE, with couplings or as a complete linear system – expand the solution space for these “individual talents”.

V-Drive servo worm gearheads: suitable solutions for any torsional backlash greater than 2 arcmin

“Whispering gearhead”, “lightweight” – both of these terms are an apt description of the newly developed V-Drive Basic servo worm gearhead from WITTENSTEIN alpha GmbH. It was developed for price sensitive applications with no high-end requirements in respect of the maximum torsional backlash. Parallel to this, the other two members of the product family have undergone a technological upgrade with regard to torque and torsional backlash: V-Drive eco has become V-Drive Value while V-Drive+ provided the inspiration for the new V-Drive Advanced. The portfolio thus includes suitable solutions for any specified torsional backlash greater than 2 arcmin.

Brushless DC motor systems enable flexible control of gripping elements

Spiders have eight legs, each of which can be moved completely independently of the others. This gives them the ability to grip onto, and clamber over, any surface rough or smooth. The new gripper spider from FILL, the Austrian mechanical engineering and plant construction company, is every bit as flexible as this arthropod’s extremities and can also be admired at the trade fair. More than a dozen brushless DC motors from WITTENSTEIN cyber motor GmbH were necessary to make this possible. As a combination of brushless DC motors belonging to the cyber® dynamic line and an identical number of servo amplifiers from the simco® drive series, they allow different linear positions to be approached steplessly without any mechanical retooling – a decisive advantage compared to pneumatic drives. The other main arguments in favour of these brushless DC motor systems were the compact design and low weight of the motors and the fact that the servo amplifiers integrate easily into the handling system’s PROFINET fieldbus environment.

Drive system with Industry 4.0 connectivity: smart electronics in heavy-duty use

Heavy-duty electric multipliers, like those built by the Ingolstadt firm of alkitronic, are used in a variety of industries: power stations, tunnel and bridge construction, mining, steel, heavy machinery and heavy-duty engines, aircraft maintenance and renewable energy plants such as wind farms, to name but a few. WITTENSTEIN electronics GmbH has come up with a customized, sensorless synchronous motor with smart electronics integrated in the housing for this manufacturer’s newest multiplier, which will likewise be on show at the exhibition stand. The motor is housed in a cylindrical frame and is easy to integrate and service. One of the special features of this drive system is that it can position without sensors at standstill yet still develop maximum torque. For the first time, the redesigned, fully digital electronics facilitate highly complex screwing processes and provide an unusual degree of control and communications intelligence, allowing the processes to be monitored and documented more accurately. A graphical user interface with display and keyboard control is also integrated; all the fundamental requirements for use in Industry 4.0 environments are therefore met, namely data logging, Bluetooth transmission and evaluation of the measurement data on a smartphone or tablet.