“WITTENSTEIN alpha in all axes” – not just the Premium Linear System but also the Value and Advanced Linear Systems have been repositioned by the company with this claim. If the high performance Premium Linear System, for instance, is used in the main axis of a machining center, the Value and Advanced Linear Systems are the ideal solution for the tool changer of the same application.

Fast system selection – all from one supplier

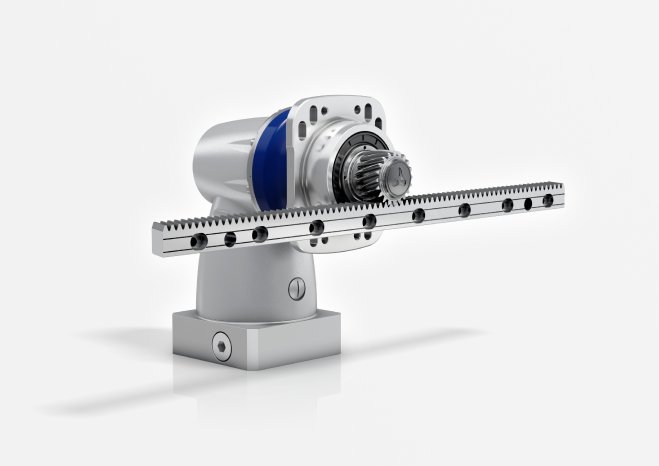

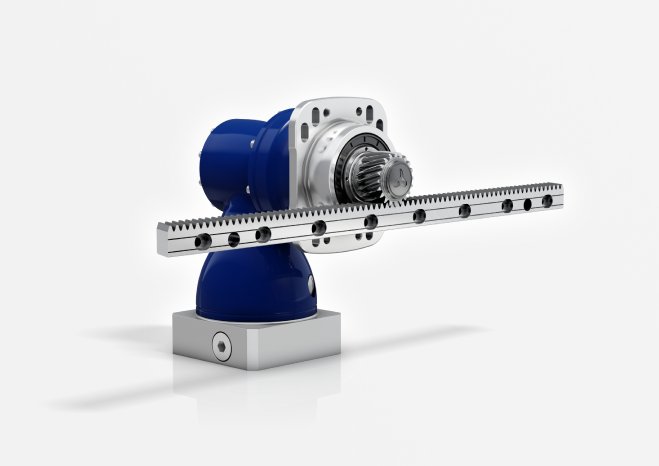

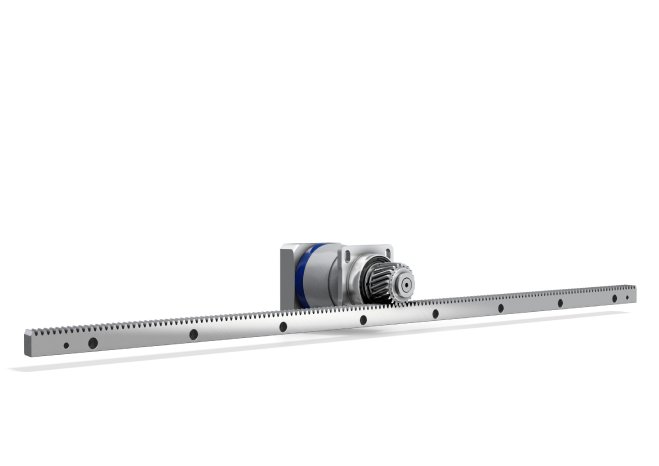

There is a fundamental correlation between the performance of a linear system and the interaction of the individual components. The gearhead, pinion, rack and lubrication system of preferred linear systems are perfectly matched for this reason. Hence, not only the individual components of preferred systems – which are available between 2 kN and 112 kN in the decentralized drive – are optimally utilized; the entire system delivers the best possible performance in terms of moving force, movement speed and rigidity. Designers can select the perfect solution fast and source everything from one supplier. All kinds of interface risks typically associated with individual sourcing from multiple suppliers are avoided in this way – even with customized systems.

Customized design interactively

Preferred systems enable a broad spectrum of regularly recurring tasks and requirements to be covered efficiently. If a customer is seeking a rack-and-pinion solution with special performance features, WITTENSTEIN alpha’s experienced sales and application engineers optimize the configuration of the drive solution using the cymex® 5 sizing software. This could entail improving the natural frequencies in the drive configuration together with the user or accommodating other specific wishes such as a configuration with master slave / drives.

Simple and efficient assembly

All linear systems are designed to ensure simple, fast and reliable assembly, be they preferred systems or bespoke rack-and-pinion solutions. The INIRA assembly system provides more degrees of freedom for designing the machine bed and less than half of the usual labor time is required for installation by the fitter – while assembly precision is increased. INIRA pinning, for instance, reduces the time to pin a rack to about a minute compared to 45 minutes with the standard method – regardless of the mounting position and module. The optional R flange likewise reduces the design and assembly effort significantly for machine manufacturers because the positioning mechanism is already integrated in the gearhead output interface. And last but not least, the flange permits even more solid and more rigid bed designs.

Suitable solutions for all axes and requirements

The new Premium Linear System takes the place of WITTENSTEIN alpha’s existing Performance and High Performance Linear Systems. The Value and Advanced Linear Systems – which are also available as preferred linear systems – are optimized for applications with lower moving force, positioning accuracy and smooth running requirements.